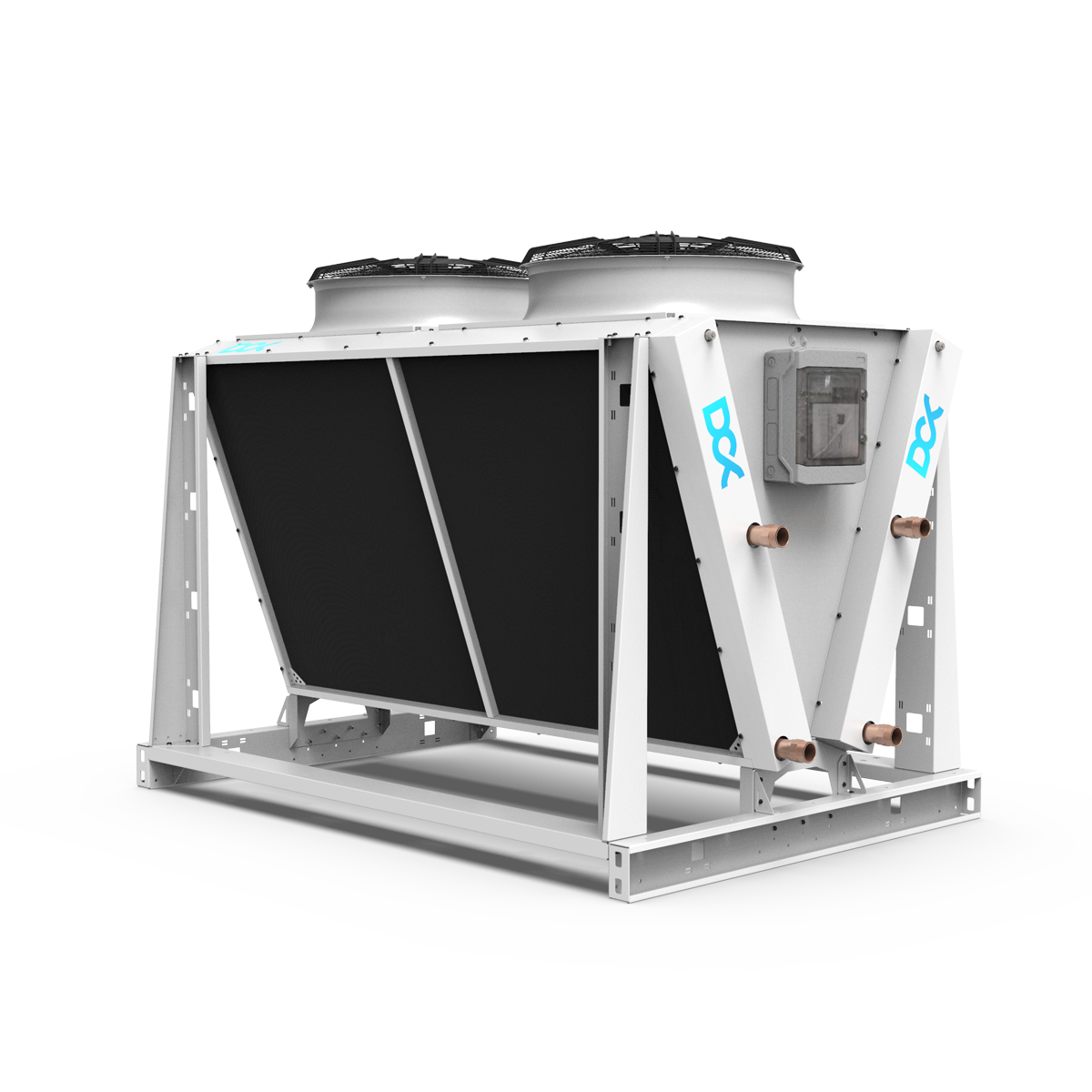

Experience a new era of thermal management for your immersion racks with the revolutionary 240 kW Dry Cooler. This innovative solution leverages advanced air-based cooling technology to deliver exceptional heat transfer capacity, optimizing your data center operations while maximizing space efficiency. Over 240 kW of heat transfer capacity in 35°C ambient conditions, exceeding 140 kW at lower temperatures (20-25°C). Extensive 200 m² heat exchange area facilitates efficient heat dissipation, guaranteeing optimal server performance and longevity. Three standard 56-70 dB fans deliver powerful airflow across the heat exchanger, ensuring efficient heat removal. Compact footprint of 200 x 160 x 160 cm allows for flexible placement, either standing or on a table-top platform. Choose high-performance mode (1.7-2.2 kW) for situations requiring maximum cooling capacity, or opt for the moderate mode that utilizes up to 40% less energy for everyday operations, promoting superior energy efficiency.

Capacity

Boasts over 120 kW of heat transfer capacity, exceeding 140 kW.

Performance

With a 200 m² heat exchange area and powerful fans, effectively dissipates heat

Sustainability

Eliminates the need for water, minimizing environmental footprint.

Energy Efficiency

Moderate mode that uses up to 40% less energy for everyday operations.

Overview

Revolutionize your immersion farm’s thermal management strategy with the innovative 240 kW Dry Cooler. This cutting-edge solution leverages advanced air-based cooling technology to deliver exceptional heat transfer capabilities, optimizing your data center operations while maximizing space and energy efficiency.

Experience superior cooling power, exceeding 140 kW in cooler environments, ensuring optimal performance for your immersion-cooled servers even in demanding conditions. This expansive surface area facilitates efficient heat dissipation, guaranteeing optimal server performance and longevity. Deliver powerful airflow across the heat exchanger, ensuring efficient heat removal and maintaining a cool and stable environment for your servers. This space-saving design allows for flexible placement, either standing or on a table-top platform, maximizing space utilization within your data center.

Tailor performance to your specific needs. Choose high-performance mode for maximum cooling capacity during peak workloads, or opt for the moderate mode, which utilizes up to 40% less energy for everyday operations, promoting superior energy efficiency and reducing operational costs. Eliminate the need for water-based cooling systems and contribute to a more sustainable future with environmentally friendly air-based cooling. The 56-70 dB fans operate quietly, minimizing noise pollution within your data center environment. Customize the system further by exploring optional components and upgrades to perfectly suit your specific immersion farm needs.

Features

- Broad Range of cooling systems – from integrated 15-40kW cooling & pumping systems, to industrial dry coolers in the range 120-240kW up to rugged 1-2MW platforms

-

Electronically controlled with automatic fan programming results with low noise levels

- Optimized for liquid cooling temperatures threshold

- Optional Adiabatic Spray / Panel System

- Compact systems with highly efficient geometry result with maximum performance & minimum footprint

- Build with rigid frames and sized to standard dimensions which enables mobility and easy relocation if needed

- CE Marked, PED EN(2014/68/EU) compliant, UL / ETL compliant

| Ninja Column 1 | Ninja Column 2 |

|---|---|

| Application | Immersion od Direct Chip cooling systems heat rejection |

| Cooling capacity (Ambient temp=35°C) [kW] | 240 |

| Cooling capacity (Ambient temp=25°C) [kW] | 280 |

| Dimensions [mm] | 2100 x 1600 x 1600 |

| Fans | 2 x 800 mm |

| Noise level [dB(A)] | 58-72 |

| Maximum power consumption [kW] | 3.6 |

| Power Standard | 400V/3Ph/50hz/1.4-0.9A |

| Fittings | 2" / DN50 or 3" / DN80 |

| Fluid temperature In / Out [°C] | 60 / 40 |

| Transport weight [kg]|[lb] | 800 | 1764 |

| Nominal volume flow [mᶾ/h] | 10.3 |

| Pressure drop (bar) | 0.37 |

Features

- Broad Range of cooling systems – from integrated 15-40kW cooling & pumping systems, to industrial dry coolers in the range 120-240kW up to rugged 1-2MW platforms

-

Electronically controlled with automatic fan programming results with low noise levels

- Optimized for liquid cooling temperatures threshold

- Optional Adiabatic Spray / Panel System

- Compact systems with highly efficient geometry result with maximum performance & minimum footprint

- Build with rigid frames and sized to standard dimensions which enables mobility and easy relocation if needed

- CE Marked, PED EN(2014/68/EU) compliant, UL / ETL compliant

System Build

240 kW Optimized Dry Cooler

Elevate your thermal management strategy with the groundbreaking 240 kW Dry Cooler. Discover the key components that power this revolutionary dry cooler: Constructed from a combination of copper coils and aluminum fins for superior thermal conductivity and maximized surface area. Offer a direct and efficient heat transfer path from the immersion fluid to the air. Significantly increase the surface area for enhanced heat dissipation. Three standard 56-70 dB fans deliver precise airflow control and efficient heat removal. Ensures optimal air distribution across the entire heat exchange area, guaranteeing consistent cooling for your immersion-cooled servers. Enables intuitive operation and adjustable cooling modes. Constructed from galvanized steel for superior strength and corrosion resistance. Shields internal components from environmental elements like dust, moisture, and extreme temperatures. Allows for flexible placement, either standing or on a table-top platform, maximizing space utilization within your data center.

Sustainable high performance computing

As computing power constantly increases, liquid cooling becomes a necessary solution to replace conventional air cooling. DCX HYDRO SYSTEM stands out as the most powerful, compact, sustainable, and energy-efficient data center cooling technology available today.

Get in Touch

We will advise, guide and support – the ideas are always free of charge!

Get your custom solution:

We need basic information to design custom liquid cooling system:

-

Quantity and general specification and dimensions of servers, ICT systems or other to be cooled components, along with power allocation per device or rack.

-

Brief overview of your project along with your main objective: better performance, water savings, energy efficiency, heat reuse, higher density?

-

Preferred liquid cooling technology: direct chip – coldplate system or immersion solution? Planned heat rejection or heat recovery strategy.

-

Country & city nearby planed location for climate data, heat transfer performance & shipping cost estimate.

Explore DCX HYDRO Components

More performance, better reliability, and more comfort. Nothing is better.

DCX HYDRO Universal Coldplates Portfolio

Instead of proprietary custom loops for one server only - a complete portfolio of open direct chip cooling cold-plates that enable you to retrofit any server!

dielectricfluids.eu

dielectricfluids.eu cryptocooling.eu

cryptocooling.eu