-

A broad range of 7 Coolant Distribution Units, including 4U rack-based CDUs and standalone In-Row CDUs with capacities reaching from 100kW up to 5MW.

-

Over 2 times higher heat transfer performance and twice more servers hosted per CDU compared to alternatives. CDUs feature multistage vertical immersion pumps which deliver superior flow rate and pressure, compared to standard centrifugal pumps found in other CDUs.

-

Open architecture of DCX HYDRO system makes both manifolds and coldplates affordable & compatible with every server platform.

-

Open CPU and GPU cold plates instead of custom-made proprietary loops for individual servers, empowers users to configure direct chip cooling server loops.

-

Direct liquid cooled datacenter containers with up to 660 server and 2MW hosting capacity enabling sustainable heat reuse.

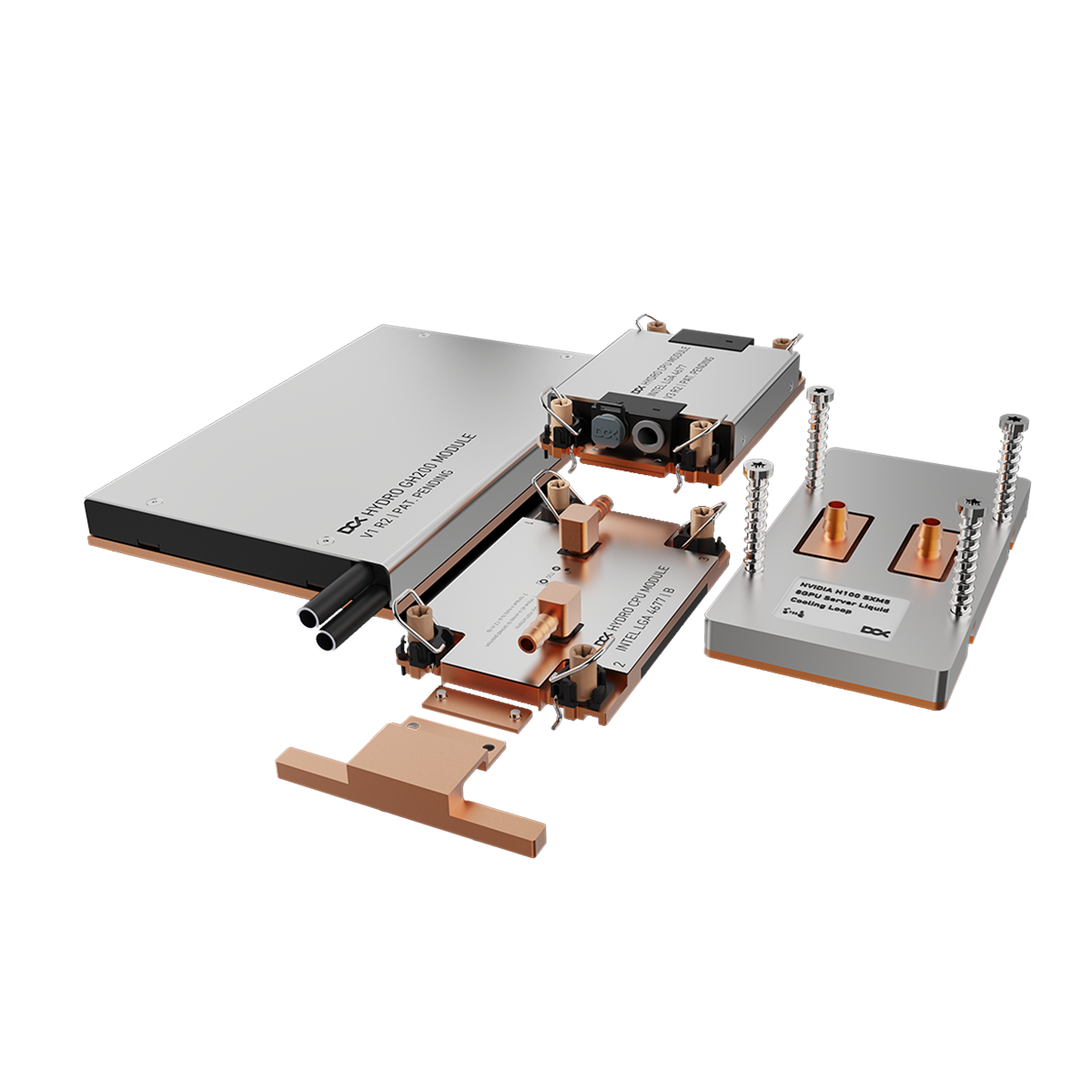

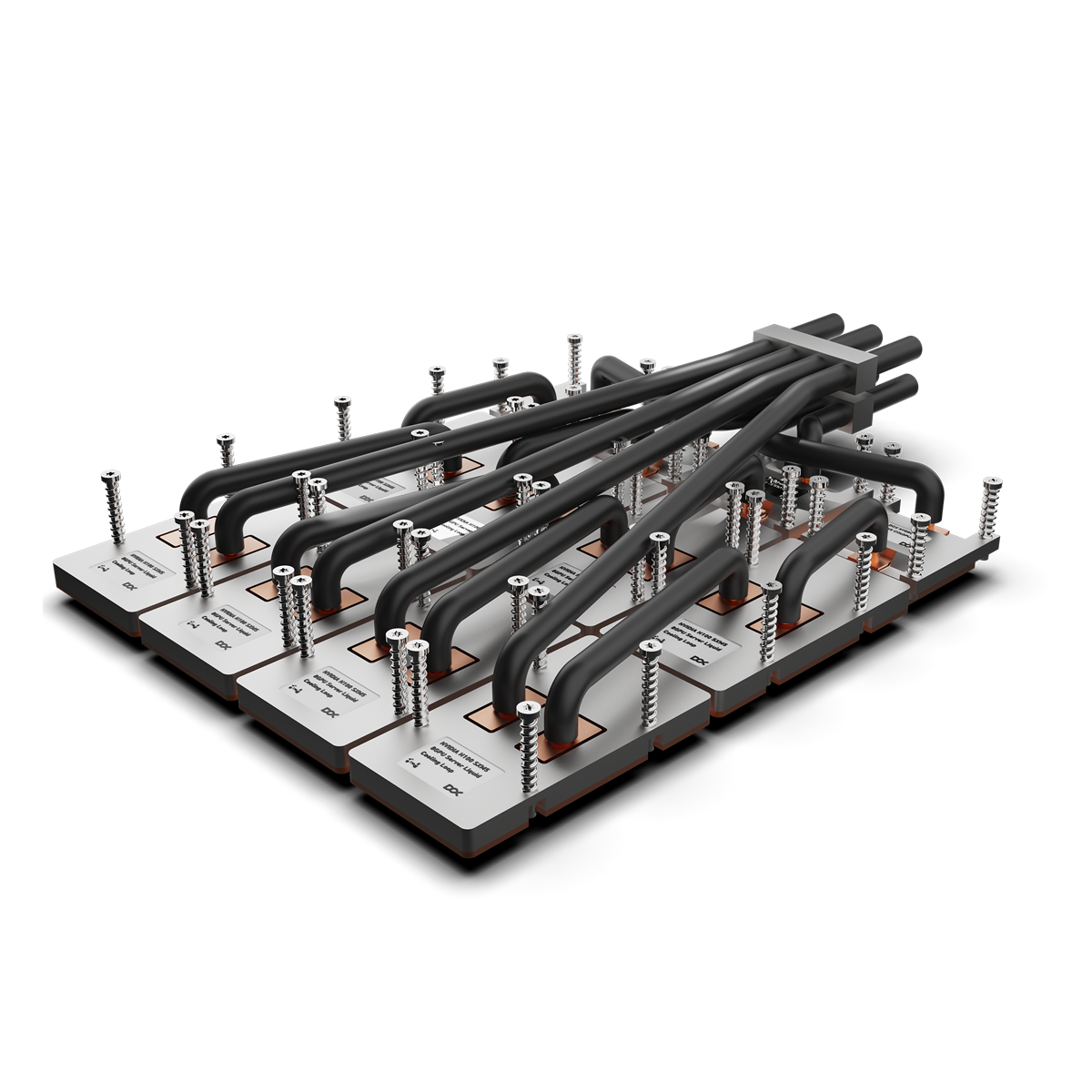

DCX HYDRO CPU Coldplates

The only Direct Chip Cooling cold plate module which allows individual user to configure server cooling loop and to implement direct liquid cooling for any server model. Using provided leak- proof tubing & quick disconnects, customers can reconfigure the cooling loop and move to the next generation server using the same DCX HYDRO coldplates. Detachable heat transfer elements enable heat transfer from over 86% of server components.

Get the SpecsheetSee More

DCX HYDRO GPU Coldplates

GPU coldplates for AI learning / GPU servers enable customers to operate safely with 50-100kW per rack capacities. DCX offers both PCIe and SXM coldplates as an easy retrofit of existing servers and GPU cards. DCX HYDRO Direct Chip Cooling system cold plates allows individual user to configure server cooling loop and to implement direct liquid cooling for virtually any air cooled server model.

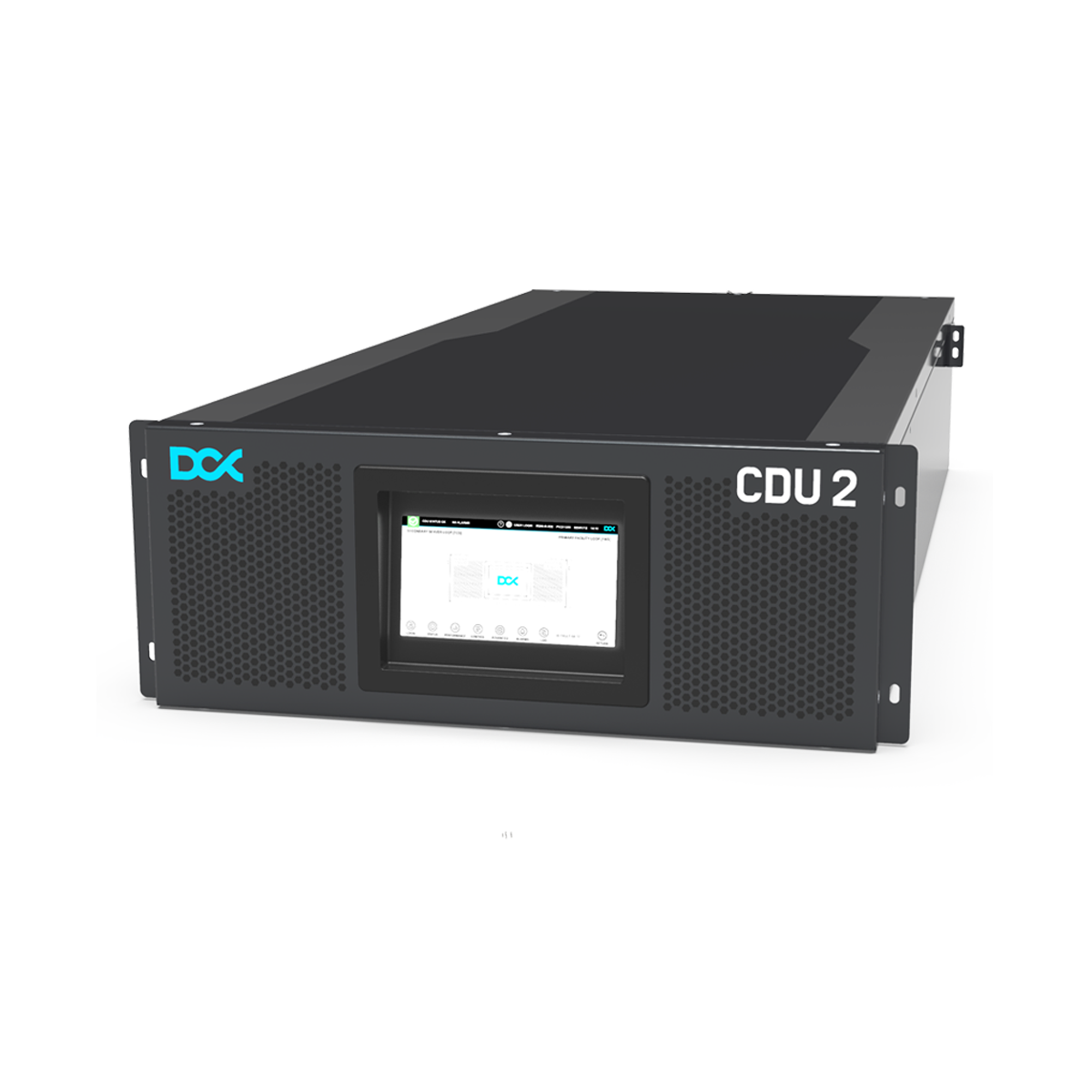

Get the SpecsheetSee MoreDCX HYDRO Coolant Distribution Units

Most powerful CDU systems in the market. A new generation of DCX Hydro Coolant Distribution Units, dedicated for direct liquid cooling of high-performance computing and standard datacenter servers. We offer a comprehensive portfolio of 7 CDUs, which, compared to market standard, deliver 2 x higher capacity and can serve 2 x more server racks per CDU than competitive solutions.

Get the SpecsheetSee More

DCX HYDRO Rack based Coolant Distribution Units

Family of in rack based CDU's, with heat transfer capacity of 170kW at average approach temperature and over 300kW at temperatures assumed by competitors. This rack based CDU's are equipped with 2 redundant multistage immersion pumps and can effectively cool multiple racks or high-powered HPC systems with twice higher pressure and flow rate than any other solution.

Get the SpecsheetSee MoreDCX HYDRO Datacenter Containers

High density liquid cooled datacenter containers with integrated redundant power distribution and CDU system fulfilling every requirement of high availability. DCX offers 1MW capable 20FT datacenter container system with 6 server racks hosting over 280 servers and 40FT sized datacenter container with 14 server racks and almost 660 servers with heat transfer capacity of 2MW. Both systems enable users to reclaim 80% of heat from the servers and connect it flexibly for different heat reuse applications heating homes, facilities, greenhouses and pools.

Get the SpecsheetSee More

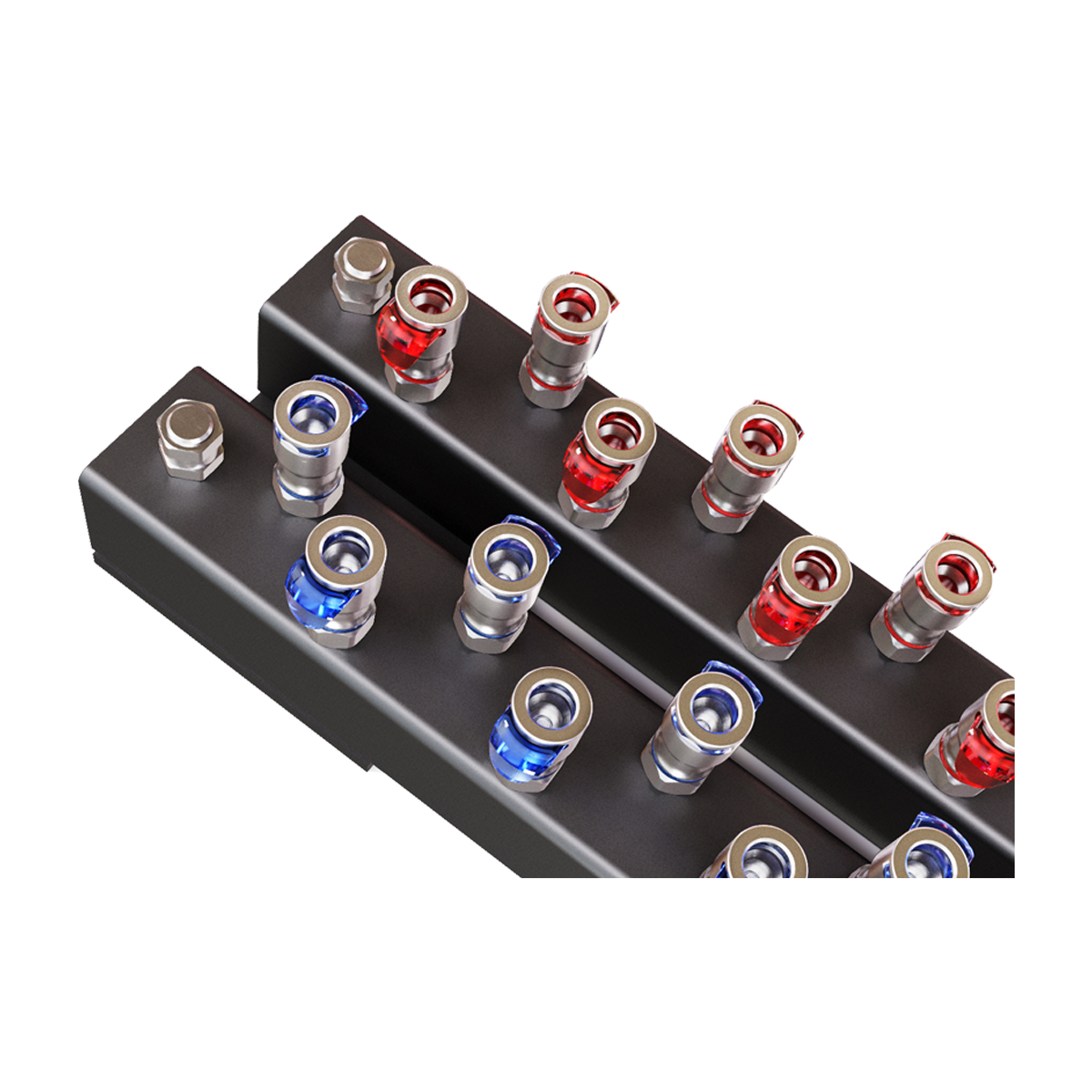

Liquid Distribution Manifolds

Proprietary manifolds are one of most expensive components of direct chip systems. This is why DCX offers affordable and cost effective manifold solutions. Dedicated to standard rack systems can be delivered in vertical or horizontal arrangement for dense blade systems. Automatic pressure release valves, air vents and wide range of quick couplings give operators a complete flexibility. We select components having in mind material compatibility and offer different solutions for quick disconnects aiming at cost effectiveness and customer satisfaction.

Get the SpecsheetSee MoreTechnology Cooling Systems

As a part of a complete offering we offer engineering services including free of charge sizing, design and also delivery and installation of TCS (Technology Cooling System) and Facility Water Systems (FWS). We select correct material for designed fluid chemistry, material compatbility & temperature range: from PPR pipping to SS316 stainless steel piping with full flow balancing and pressure safety.

Get the SpecsheetSee More

dielectricfluids.eu

dielectricfluids.eu cryptocooling.eu

cryptocooling.eu