DCX HYDRO CDU 9 is a standalone Unit Coolant Distribution Unit designed to cool a group of high-density server racks. This cost-effective but enterprise-class CDU, equipped with unique immersion pumps, delivers over 900kW heat transfer capacity at 10C approach temperature which supports 21 server racks with around 800 1U servers.

CDU 9 features all advanced capabilities: redundant pump design, dynamic condensation-free control, automatic coolant leveling, automatic leak detection and complete remote control of all important parameters. A perfect solution that provides responsive, high-capacity cooling for HPC or GPU server nodes, and it only requires ASHRAE W3/W4 warm water to solve all cooling challenges of power–dense racks. The compact dimensions of CDU 9 allow for quick retrofitting of existing data halls with a liquid cooling system. This CDU will fit any data room environment with in-row or technical corridor placement. The system can be integrated with all standard server racks providing energy-efficient cooling & intelligent controls.

DCX offers CDU9 along with secondary loop (TCS) components including DCX Liquid Distribution Manifolds, quick disconnects, and cold plates. The complete solution will provide the exact, optimal cooling performance that your servers need, keeping your operation environmentally sustainable.

Capacity

Up to 800 servers or 20 server racks per one CDU!

Performance

Up to 900kW of heat transfer capacity!

Sustainability

Enables heat reuse with up to 60°C return temperature!

Energy Efficiency

Adaptive energy consumption up to 11kW per 20 server racks

Overview

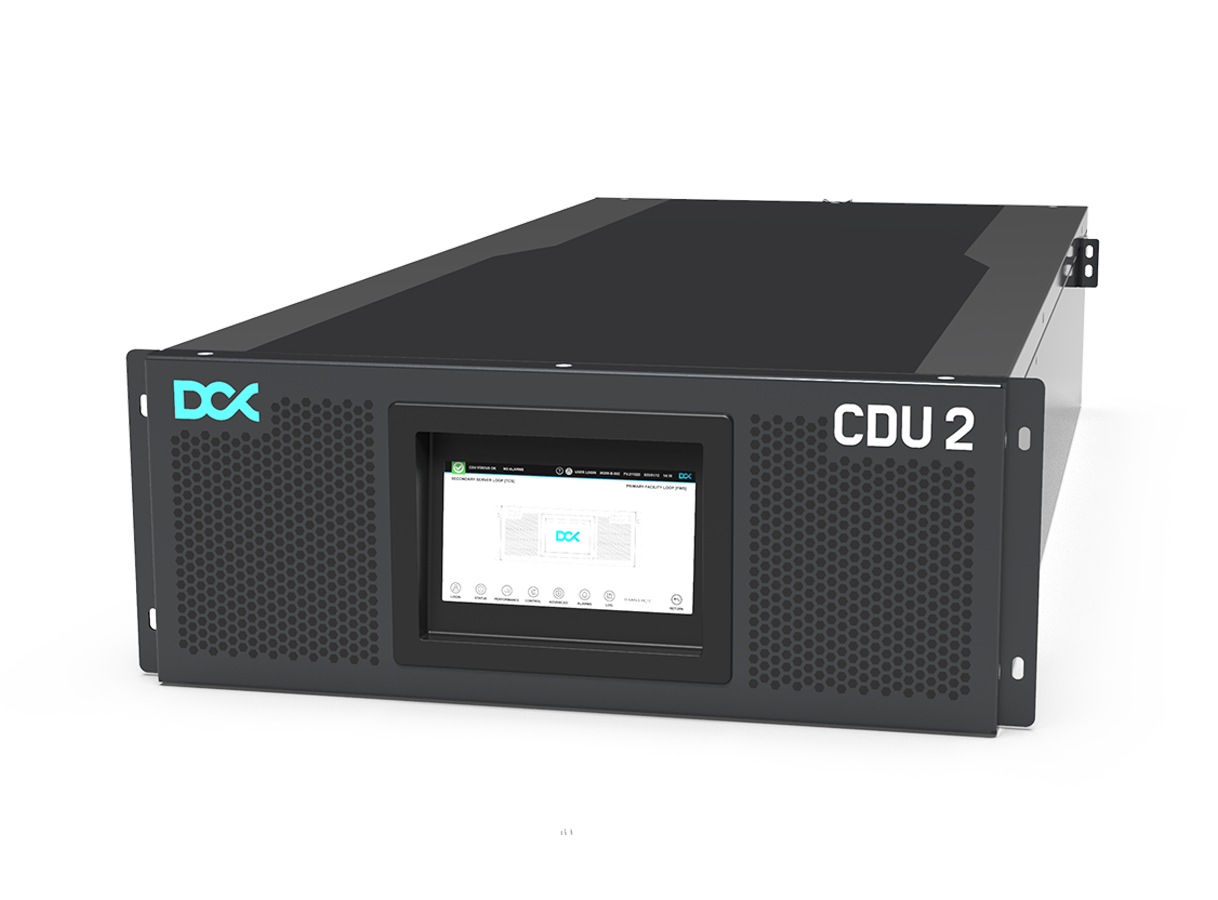

DCX offers a full range of cost-effective but enterprise-class Coolant Distribution Units (CDUs) for hydro miners and direct liquid cooling systems that support advanced and power-hungry hydro miner models. We propose multiple CDU systems designed to fulfill specific requirements from small scale to large liquid cooling operations, including the in-rack CDU 1 & 2 models, as well as CDU 3, 6, 9, and 12 with a rated capacity from 300kW to 1200kW per single CDU system. These CDU’s are designed for high-powered miners or mining servers and offer advanced features such as variable-speed pumps, full condensation control, cooling loop separation, redundant components, adaptive operation, energy-efficient cooling & intelligent controls with full remote control of the system.

DCX CDU’s, are standalone, rack-based Coolant Distribution Units (CDU), a key component in direct chip cooling (DLC) or hydro cooling systems. Those CDU’s with a rated cooling capacity from 300 to 1200 kW offer adaptive and efficient cooling of hydro miners with full condensation control. The CDU’s are designed to regulate the flow and temperature of the coolant and ensure that each component in the cooling loop receives an adequate supply of flow to maintain the desired operating temperature. It is also responsible for monitoring the temperature of the coolant and adjusting the flow rate as necessary to maintain the temperature below the dew point protecting the precious electronics from condensation. DCX CDU’s provide effective separation of the facility circuit and secondary circuit which allows controlled fluid quality and ensures that the cooling fluid in a data center environment can be kept to a minimum volume, is closely controlled for flow, pressure & temperature, and can be accurately maintained for fluid quality.

Some of the key features of a DCX CDU’s include:

- High flow rate: designed to deliver a high flow rate of coolant to ensure that each component in the cooling loop receives an adequate supply of coolant.

- Full remote monitoring: contains temperature, flow, and operation sensors that monitor the temperature of the coolant and adjust the flow rate as necessary to maintain a consistent temperature.

- Redundancy: designed with redundant pumps and other components to ensure that the cooling system remains operational in the event of a failure.

- Energy efficiency: CDU’s are designed to be energy-efficient, with features such as variable speed pumps and advanced control systems that help to minimize energy consumption.

Overall, our Coolant Distribution Units play a critical role in the operation of direct liquid cooling systems and hydro systems in data centers, helping to maintain the desired operating temperature and ensure the reliability and efficiency of the cooling system.

Features

- Supports twice as many servers, CPU’s and GPU’s than other CDU’s

- Multi-stage immersion pumps deliver twice the pressure and flow rate of standard pumps.

- Enterprise-class system high availability & redundancy

- Adaptive efficiency, loop separation and condensation control.

- Complete portfolio of 7 CDUs tailored to meet diverse cooling requirements

- Wide range of systems, ranging from 100kW per 1 rack to 5MW and 100 server racks per single CDU

| Ninja Column 1 | Ninja Column 2 | Ninja Column 3 | Ninja Column 4 | Ninja Column 5 | |||

|---|---|---|---|---|---|---|---|

| Product model | CDU 9 | ||||||

| Coling capacity [kW] | 900 | ||||||

| Approach temperature [°C] | 10 | 3 | |||||

| Operation condition | Primary side | Secondary side | Primary side | Secondary side | |||

| Coolant | Facility water | DI-water | Facility water | DI-water | |||

| Flow [m3/h] | 52 | 52 | 52 | 52 | |||

| Output rated dP (bar) | / | ≥2.8 | / | ≥3.2 | |||

| Rated inlet temperature [°C] | 35 | 63.1 | 35 | 52.8 | |||

| Rated outlet temperature [°C ] | 53 | 45 | 49.8 | 38 | |||

| Cooling capacity margin | 20% | -1.5% | |||||

| Transport weight [kg / lbs] | 1090 / 2403 | 1223 / 2696 | |||||

| Operation weight [kg / lbs] | 1390 / 3064 | 1610 / 3549 | |||||

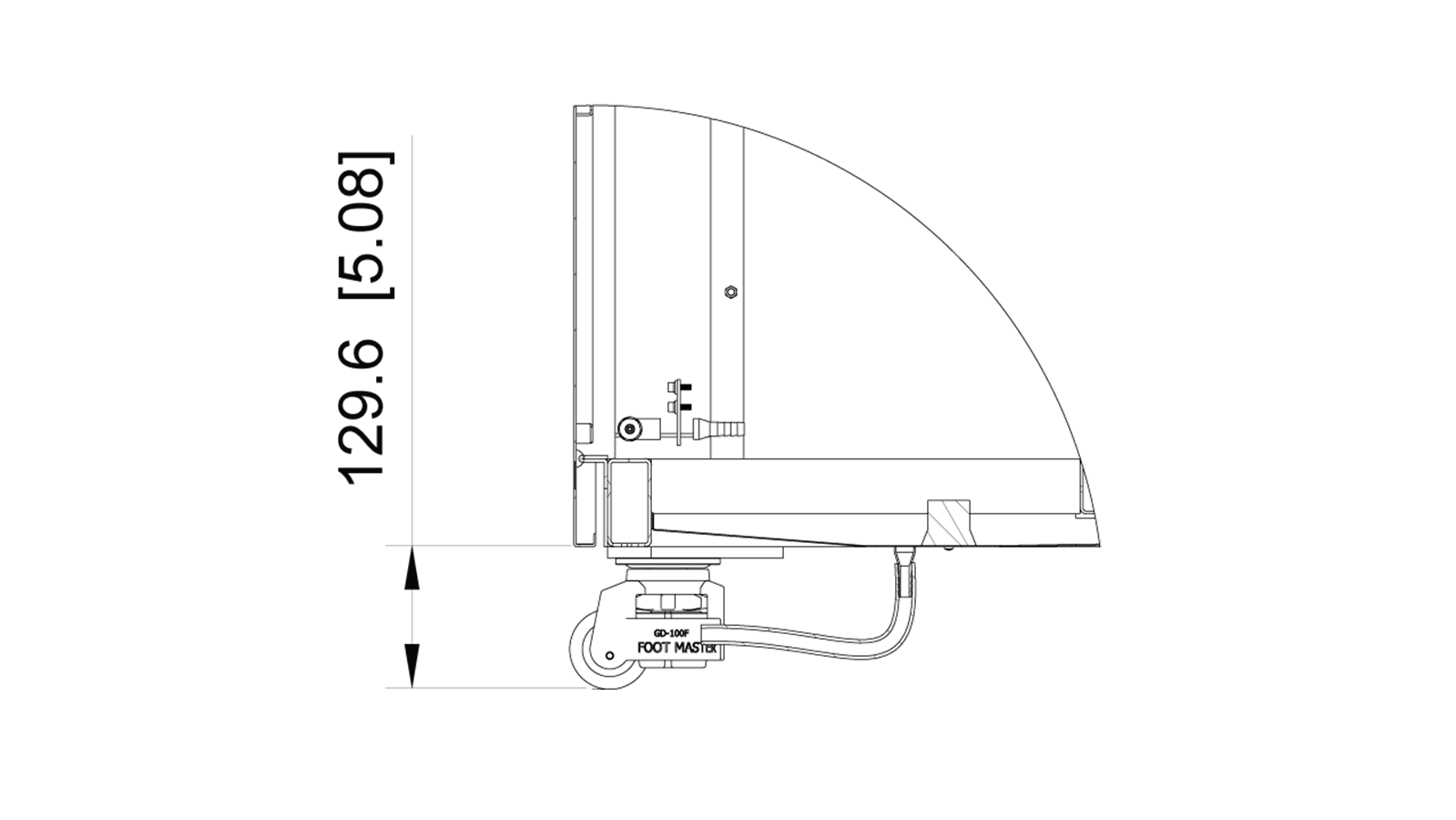

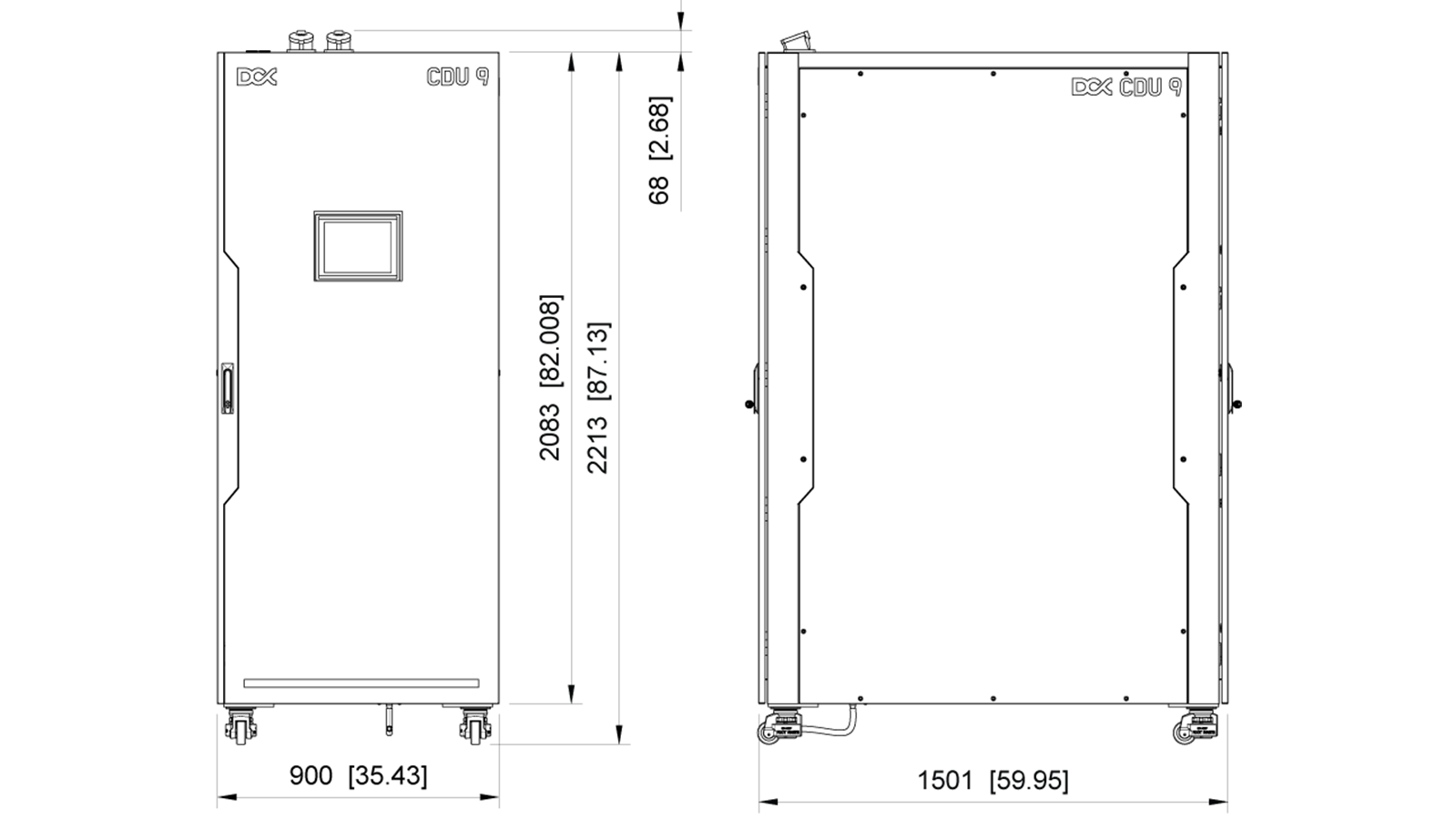

| Height [mm] | Width [mm] | Depth [mm] | 2213 | 900 | 1500 | ||||||

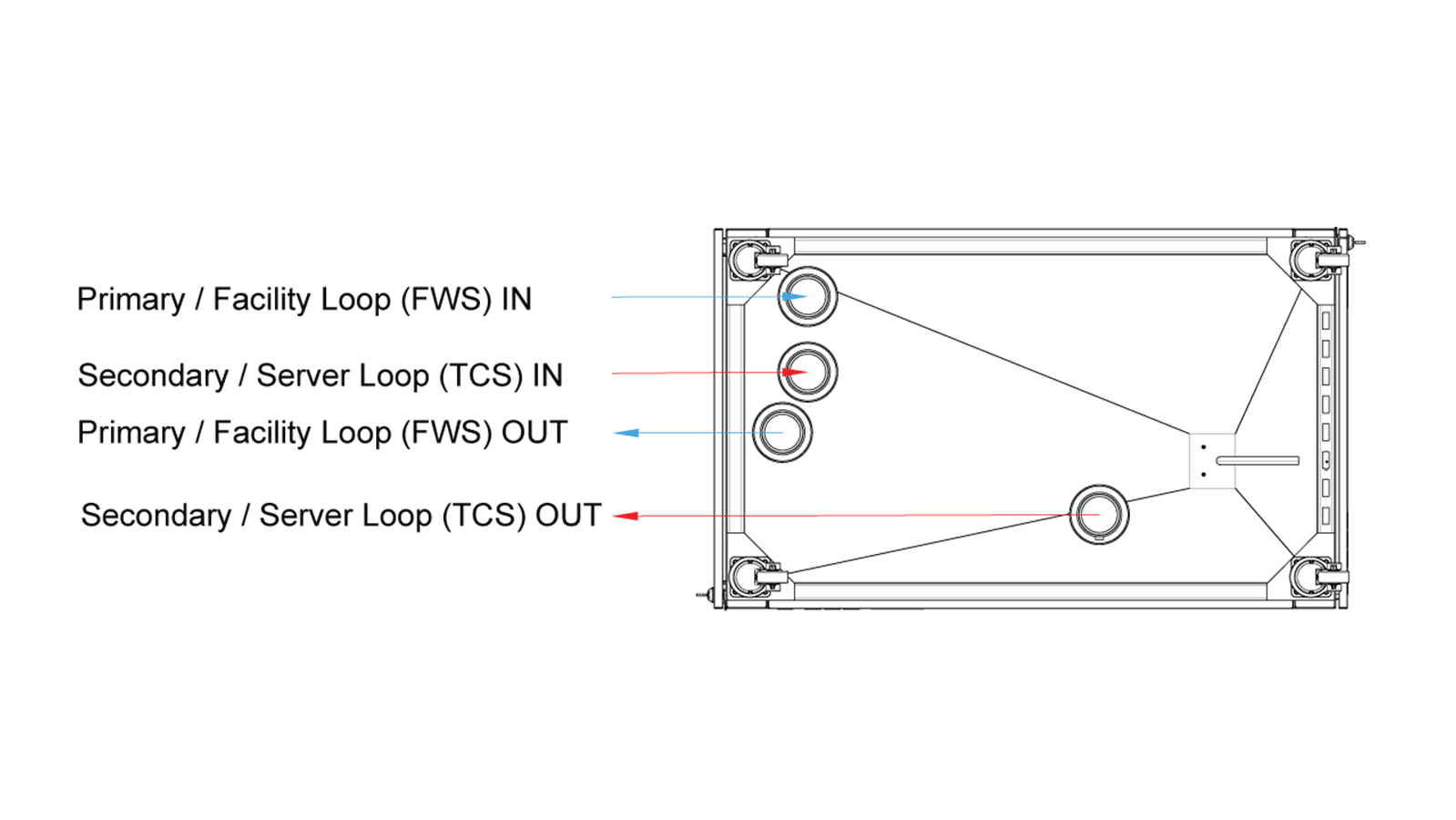

| FWS liquid connector style and dimension | Tri-Clamp 3.5" | ||||||

| TCS liquid connector style and dimension | Tri-Clamp 3.5" | ||||||

| Max. Power consumption [kW] | 11 | ||||||

| T-V coefficient [C*L] | 6.4×10⁴ | ||||||

| Power specifications | 3P AC380V 50/60Hz | ||||||

| Working environment T&H | 0~50°C/ RH5~85% | ||||||

| Noise Level [dB] | 65 | ||||||

Features

- Supports twice as many servers, CPU’s and GPU’s than other CDU’s

- Multi-stage immersion pumps deliver twice the pressure and flow rate of standard pumps.

- Enterprise-class system high availability & redundancy

- Adaptive efficiency, loop separation and condensation control.

- Complete portfolio of 7 CDUs tailored to meet diverse cooling requirements

- Wide range of systems, ranging from 100kW per 1 rack to 5MW and 100 server racks per single CDU

System Build

CDU 9 InRow Coolant Distribution Unit

Enterprise class Coolant Distribution Unit, with 900kW of heat transfer capacity at average 10°C – 15°C approach temperature. This CDU system will support a complete rack groups filled with liquid cooled servers.

This unit is designed for high density servers cooling and offer advanced features such as variable-speed pumps, full condensation control, cooling loop separation, redundant components, adaptive operation, energy-efficient cooling & intelligent controls with full remote control of the system.

CDU is equipped with 2 redundant multistage immersion pumps and can effectively cool multiple racks or high-powered HPC systems with 2 x higher pressure and flow rate than any other solution. With the double pump redundant design, replacement and maintenance does not interfere with high availability of the system. Maintenance can be performed without downtime as all critical components are redundant.

Get in Touch

We will advise, guide and support – the ideas are always free of charge!

Get your custom solution:

We need basic information to design custom liquid cooling system:

-

Quantity and general specification and dimensions of servers, ICT systems or other to be cooled components, along with power allocation per device or rack.

-

Brief overview of your project along with your main objective: better performance, water savings, energy efficiency, heat reuse, higher density?

-

Preferred liquid cooling technology: direct chip – coldplate system or immersion solution? Planned heat rejection or heat recovery strategy.

-

Country & city nearby planed location for climate data, heat transfer performance & shipping cost estimate.