Liquid Immersion Cooling – basic informations:

Take full control of the power Salient has to offer with our new exciting page builder. You’ll be grinning in delight when you see just how easy it is to create stunning layouts with little effort.

Take full control of the power Salient has to offer with our new exciting page builder. You’ll be grinning in delight when you see just how easy it is to create stunning layouts with little effort.

The days of being overwhelmed by long documents without any visual guidance are over – We have an entire video tutorial series available for you that’s narrated through the duration.

The looks & functionality you’ve been dying for are finally easily accessible. We know you’ll enjoy the freedom to showcase your content in the way that it deserves.

Immersion cooling is a process of cooling electronic components (ASIC miners, GPUs, CPUs, servers, etc) by submerging them in the specially engineered fluids. It is a non-conductive, dielectric fluid that looks like water, but does not shortcut electronics. The fluid has a great heat absorption capacity which is 1500x better than the heat transfer capacity of air.

Miners that are immersed use no fans (with span spoofers or with custom firmware) so you don’t need any air handling, additional fans in the facility, no noise protection. So the operation can be done in a commercial or residential areas. You can connect then to water loop or to drycooler we deliver

By circulating the fluid through the hardware devices heat is removed and transported away to an external heat rejection device – dry cooler or heat exchanger or any water loop. It also allows heat reuse applications like heating home, office, warehouse, swimming pool, greenhouse…

Liquid cooling with a dielectric (non-conductive) fluid offers a variety of benefits over traditional air cooling. Let’s list just a few of them, that influence your mining operations.

Not exactly. You should think about it as liquid cooling or cooling with a dielectric fluid. Unlike gaming PC or overclocked CPUs that can be cooled with water, we use a specially designed fluid that is removing the heat from devices immersed (or submerged you can say) in that liquid. The fluid is non conductive – dielectric. So there is no risk of damaging your electronics with water that will kill the components as it might happen with DIY water cooling of PC.

Our dielectric liquid has great heat capacity and is materially compatible with electronics – so it will not damage the expensive ASIC miners.

Single phase means that during the cooling process the fluid is not changing its physical state. It remains fluid all the time. It means, it’s not boiling and not evaporating. Such systems are very affordable and do not require lots of maintenance efforts during their operations. Fluid can remain in it for years if kept clean and away from water.

What is a dual-phase cooling? In such a type of process, fluid is heated until it starts to boil and changes its state from liquid to vapor. To achieve it fluid must absorb a large amount of energy. This process is very efficient for its cooling capabilities (better than single-phase and about 4000x better than free air cooling) but it also requires a much more complicated system (with chillers, vapor condensers) and must be sealed very precisely. Dual-phase fluids are at least 10x more expensive than typical fluids used in a single-phase system. On top of that, it requires lots of maintenance and constant leak checks.

You want single-phase immersion cooling. Really. Single-phase means you are using special synthetic oil made for electronics components cooling. The cost of engineered fluid is approx € 216 or $ 241 per 25 liters or 6.6 gallons. This makes that economic solution as the fluid does not evaporate, the fluid lifecycle is almost endless, and additionally, it can be filtered/reconditioned multiple times.

Dual-phase system requires special synthetic/fluorochemical coolant available at many suppliers but usually known under the brand name of 3M – Novec”. The fluid evaporates (boils) at the temperature of 61C. It evaporates quickly so it requires special hermetic sealed enclosures. Usually, people trying to use that fluid loose lots of money as 1kg (0.8 liters) costs approx $ 60 – it’s 6 times more than synthetic engineered fluid. So this is why you want single-phase system.

Simply saying, if you are looking for cryptocurrency systems cooling option – a single phase is for you. If you’re a millionaire and you’re running a large datacenter, you can afford dual-phase cooling. Remember that fluids used in dual-phase cooling are not only extremely expensive but also harmful for your health (when you inhale its vapor) but also for the environment, having one of the highest GWP parameter (Global Warming Potential) among all other toxic substances

With DCX immersion system you can cool virtually any kind of electronic hardware like IT equipment – servers, switches, storage (SSD or helium HDDs), GPU or ASIC miners, or any other kind of electronics you need to cool.

A single loop means that the fluid is cooling your miners and then goes to the dry cooler, where is chilled, and goes back to the enclosure as colder fluid. It’s simple as it doesn’t require additional pumps or heat exchangers, but you must consider that precious coolant must fill the whole setup including tubes, pipes, and the dry cooler itself. For our smallest system, ~30 l of fluid is required just for that, but it’s a good ratio: money to simplicity and value.

Dual loop systems are a bit more complicated than a single loop, but much better for bigger installations, especially with large dry coolers or for distant placement of the enclosures and cooler. A primary loop is filled with a water-glycol mixture which is cheap and very popular. The dry cooler and all pipes are filled with it. Sometimes it might be hundreds of liters.

A secondary loop is created on the enclosure level. A small pump is rotating the fluid through the brazed plate heat exchanger. There the coolant is chilled with the water out of the primary loop. These two fluids are not mixing with each other.

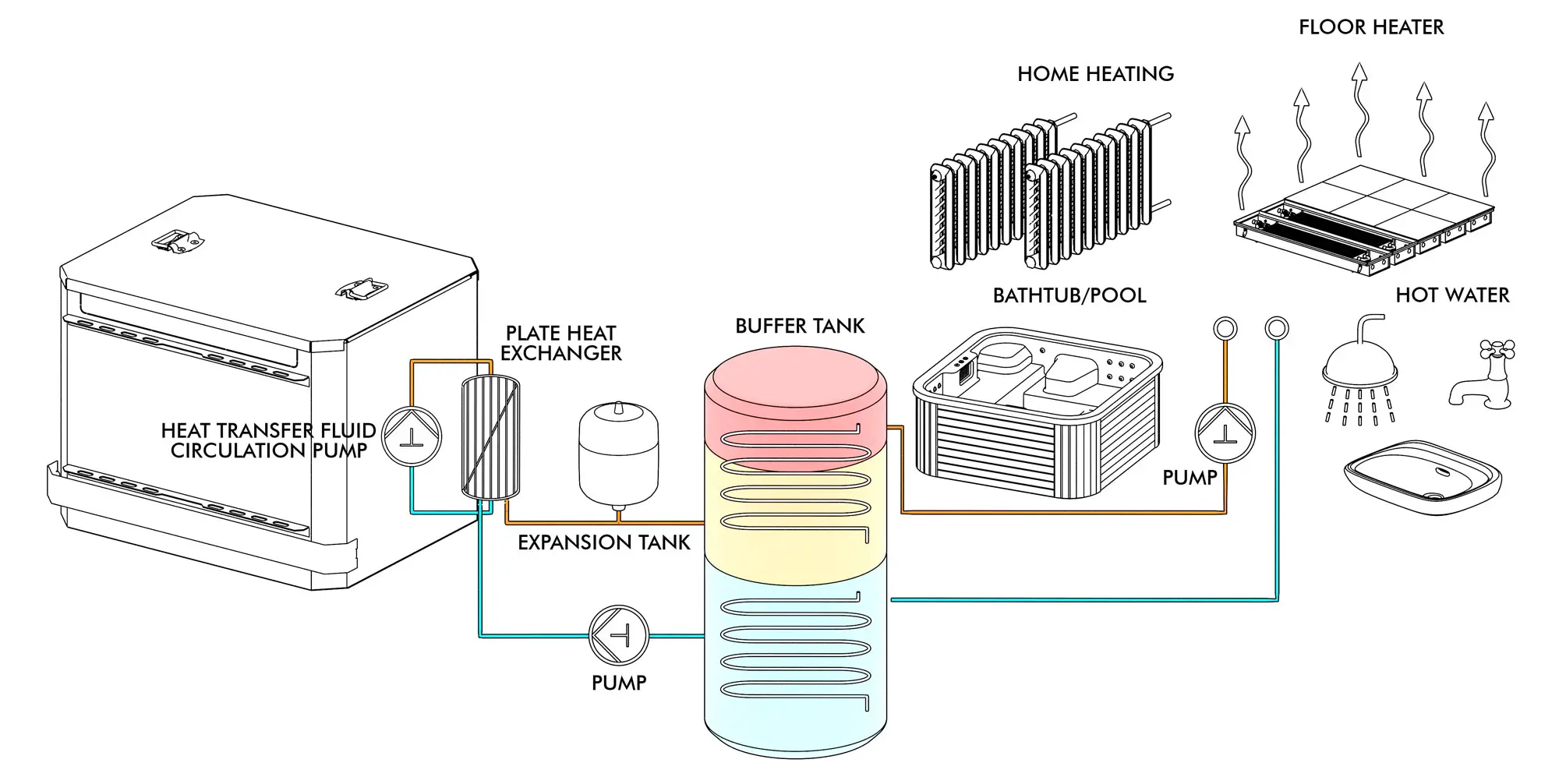

Dual loop systems are the best for heat utilization, as you can connect them with easy to your facility heating system (might be home, office, swimming pool, greenhouse…). By reusing the heat you can make your mining operations more profitable and shorten the ROI time.

You need enclosure or tank or bath filled with dielectric fluid, that will house your miners. The tank needs hydraulic fittings with correct diameter that will provide inlet and outlet of the fluid. The fluid must circulate, so we need the pump that will provide enough liters per minute flow. The fluid goes through the miners, takes the heat and warms up. This hot fluid must be circulated from the enclosure – so we need some heat exchanging or rejection device. It can be just a brazed plate heat exchanger that has a “hot” and “cold” side. You can connect to the plate heat exchanger for example tam water (but that would waste so much water) or the dry cooler. So from the enclosure, you run the tubing we provide to the dry cooler. Since dry cooler requires fresh air it must be placed somewhere outside the building, ideally under the sunshade, on the north side of the building. That’s it: an enclosure with fluid and miners, pumps that circulate the fluid, tubing, and heat exchanging device as a dry cooler.

Miners must be prepared with custom firmware so the lack of fans will not be a problem for the system and sometimes small changes (removal of thermal paste from ASIC chips or PSUs).

We design, manufacture, and deliver all components of the immersion cooling system: enclosures, dielectric cooling liquid, heat exchangers, dry coolers, all complimentary components like switchgear, monitoring sensors and software, fittings, tubing, accessories, pumping stations, etc. We serve customers that require a simple single enclosure, rack systems, and container or scale-out installations.

Just a few simple steps:

New miners require

Used miners require:

The general rule is to:

After immersion – no dust, no corrosion, no burned boards as the dielectric fluid protects from overheating, vibration, shortcuts, dust etc.

How to remove the heat?

as described on the installation examples and our quick video startup manual The cooling system requires a heat rejection device. The immersion system is used to transfer the heat from the miners in a silent and very effective manner. But it also requires some device or loop where that 20-30-40-80-120kW heat will be received. Because we use hot mining method (the temperatures in our enclosures may reach 60C/140F and above, we have very effective heat transfer, even in a hot or humid climate. Whether its single enclosure or rack or multiple racks – we have 3 options to connect to our system and remove the heat :

1. water connection to home/facility heating or cooling loop

2. water connection to the tap water

3. or connection to the dry cooler.

In this setup, our Liquid 2 Liquid (L2L) Immersion Enclosure has its own pump and heat exchanger which circulates internally our dielectric heat transfer fluid. Thermasafe R dielectric liquid is very effective at heat pickup. Fluid circulates internally and takes the heat from the immersed miners. Then the heat is transferred with the enclosure brazed plate heat exchanger to external water or water-glycol loop. As mentioned it can be tap water/home heating loop / direct connection to the pool or nearby lake – everything is possible! But what is most convenient is the connection to external dry-cooler.

Description of the available options:

ad 1. At home, you can use a connection from our dual loop enclosures to the heating loop. In moderate or cold regions most of the homes will have own separate heating/cooling loop. This local system can reuse the heat from the miners if needed, and there will be multiple contractors available to connect it to your loop without andy problem. The heat from the miners can heat up the home radiators, the pool, home hot water boiler, or even jacuzzi. And that can be connected by local heating services/installation company

ad 2. If you live in a flat you use tap water. The problem may be the bill for the water but you have the silent operation of 20-60 miners at your home. Water connection requires 0.5 to 1 m3 of water per hour. Our L2L enclosures can be connected to tap water without any additional investment.

ad 3. Dry coolers are the most effective way to remove the heat. They can be standing or table-flat dry coolers. They do generate some noise but it’s just 51-55 dB(A) 10m away. Dry coolers must be placed outside – near the building or on the flat rooftop of the building. It is ok for commercial or industrial area, but rather not for residential / housing areas. The dry cooler is a close loop system so no water is wasted – it circulates the same water/glycol mixture.

We have a broad portfolio of dry coolers – see them here. And there are 3 basic types quickly available:

– a) 32kW (35C outside) / 42kW (20C outside) dry cooler. A small system for single enclosure for a single enclosure has its own pumping system that will circulate the fluid for a 10-20 meters of tubing.

– b) 80kW dry cooler for 2 or 3 enclosures with limited capacity – require pumping station which we also deliver.

– c) 127kW dry cooler – larger 2 x 2 m dry cooler that supports single rack with maximum capacity – require pumping station which we also deliver.

Cryptomining Immersion Enclosure or Cryptomining Immersion Rack has multiple options to remove the heat. With the small help of the chiller unit, they can use an additional source of cold water, even in very hot regions or countries. The L2L enclosures can be also installed as a part of a bigger system and used for heat reuse. A 99% of the heat from the miners can be reused for any commercial application (farming / drying ) or home/company heating.

All our systems are built for easy scale from single enclosure, to multiple racks. We also took into account flexibility of the solution. Our enclosures may be installed with a simple “Ikea style” setup or connected to facility heating / cooling loop at your home, garage, workshop or business. Please see simplified drawings of possible installations setups.

Designed for ease of use and simplicity. Immersion is easy! You get one enclosure, dry cooler and 10 meters of tubing. The setup is quick and does not require any special skills or professional knowledge.

The enclosure should be placed inside of your workshop / garage or facility, and dry cooler – outside so it has access to the fresh air. We use a large 24-30kW rated dry cooler with dual fans and temperature controller. In regards to the enclosure, you need to take into account that it will be quite heavy when filled with hardware and heat transfer fluid so it should be placed on the ground.

We sell those systems without or with 150L of Heat Transfer fluid. Miners should be placed tightly in Immersion Mining Enclosure, gaps between the miners avoided, empty spaces filled with containers so the fluid will be forced to go through the miners or GPU cards and not around.

The whole setup takes just connecting two components with tubing, filling the enclosure with fluid so it goes over the dividing chamber and starting the system. Fans on dry cooler will start when the fluid temperature goes over 40C/104F. Miners should be placed vertically in to the enclosure and fan emulators or custom firmware should be used. That’s it! We will support you on setup and provide video manuals on connecting and starting the system.

The same Immersion Enclosure but delivered with hydraulic fittings, brazed plate heat exchanger and energy-efficient almost silent pump system. If you have facility (home, office, workshop) heating / cooling loop, you can connect our enclosure and reuse the heat from miners. Providing continuous 40-50C /104-122F to supply home installation in cold season.

An ideal solution for colder regions to supply heat to radiators, pool, jacuzzi or floor heating. Still, for hot season you can purchase drycooler which will extract excess heat. The most flexible system you can get and connect.

Ideally connected by local home installations / heating contractor, but it may be also configured by any DIY type person with 1 inch connectors from our plate heat exchanger to home buffer tank.

Dual loop system is an ideal solution for colder regions to supply heat to radiators, pool, jacuzzi or floor heating. Still, for hot season you can purchase dry cooler which will extract excess heat. Dry-cooler cann be connected to the home loop using own auxiliary low-power pump or without, using just facility flow. The most flexible system you can get and connect.

Ideally connected by local home installations / heating contractor, but it may be also configured by any DIY type person with 1 inch connectors from our plate heat exchanger to home buffer tank.

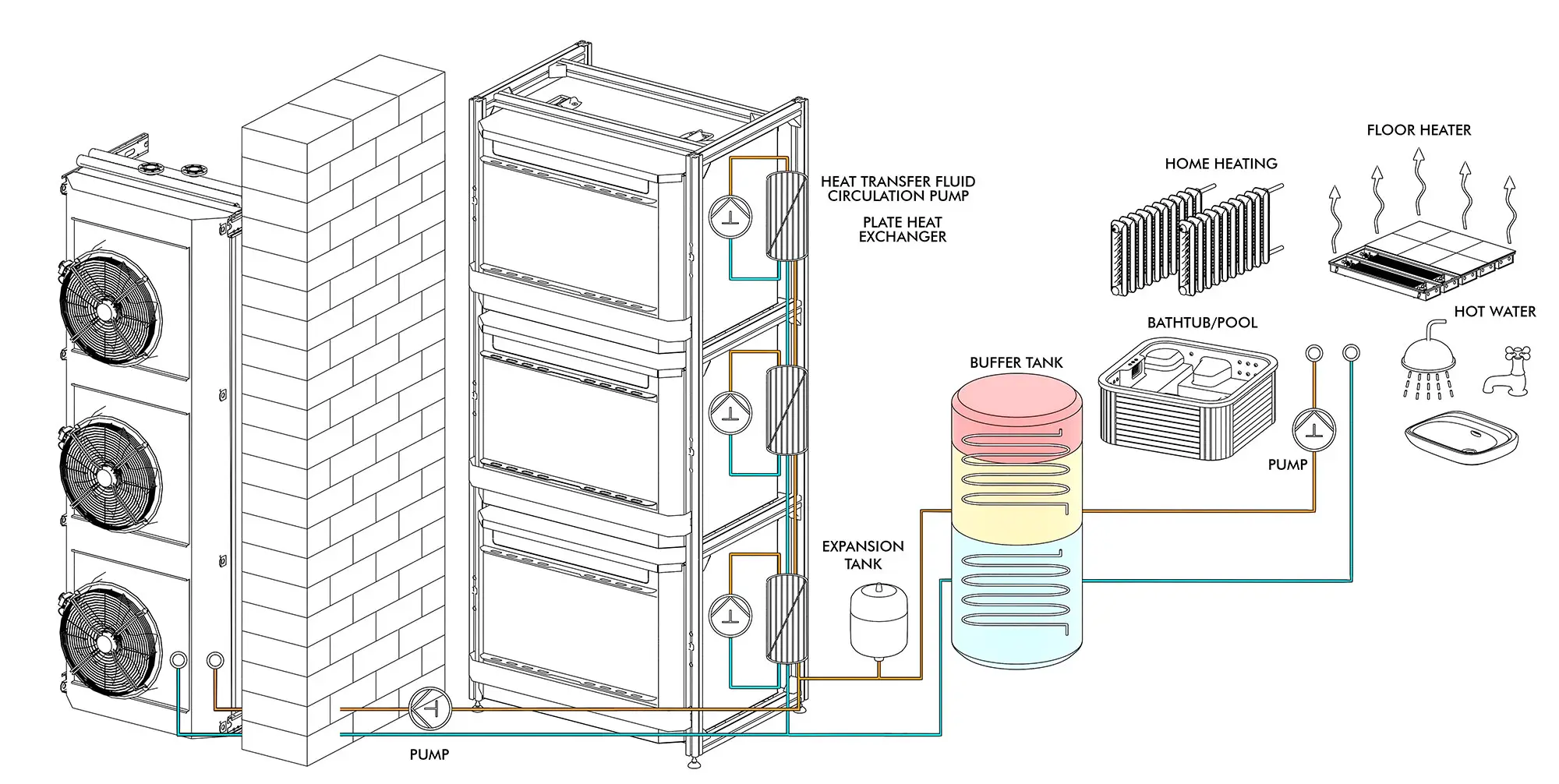

All our systems are built for easy scale from a single enclosure, to multiple racks. If you need more than a single enclosure we offer scale-up rack systems. Using Universal Enclosures as building block they occupy 1 sq. meter of space, but provide a huge 24xS17 or 20 M20s density. Those are connected to external larger dry cooler, or facility heating/cooling loop at your home, garage, workshop or business. Please see simplified drawings of possible installations setups.

Our rack system is based on Dual loop Universal Immersion Mining Enclosures with custom aluminum frame and table which allows middle enclosures to be slide out from the rack for maintenance. Originally with 3 enclosures but might be stacked to 4 enclosures. This system may be delivered with two types of heat rejection: single enclosure – single loop with dry cooler, or all enclosures connected to facility loop. We recommend the second solution which allows for greater flexibility and scalability.

In scale-up scenario one rack with 3 or more dual loop enclosures connected in series. Each enclosure has own brazed plate heat exchanger and low power, energy-efficient pump. Heat transfer fluid circulates only in enclosures. On the other side, we would use a typical water/glycol heating loop that may reuse the heat for facility purposes or reject the heat to a larger 50-70-100kW dry cooler. Both solutions provide unparalleled density and scalability.

We suggest that such a rack system or dry cooler should be installed by a local contractor which specializes in heating/cooling systems.

Rack system transfers from 50 to 70kW of heat so it requires larger heat rejection device. We suggest dry cooler as 50-60C fluid can be easily and cost-effectively extracted to air without air conditioning, chillers and water towers. The 50-100kW range dry-cooler will be connected to the home or facility loop using own auxiliary low-power pump.

Dry coolers are flexible and easy to size and may be upgraded to any heat load by adding more modules in series. They will use convection for most of the time and are simple to operate. When properly sized for the local climate, the fans on a dry cooler should only be operated for no more than 20% of the time and only during the hottest time of day. They also require very low maintenance, so they do have lowest operation cost from any other heat rejection methods.

Ideally connected by local home installations / heating contractor which can help you to size and maintain your installation in the long term.