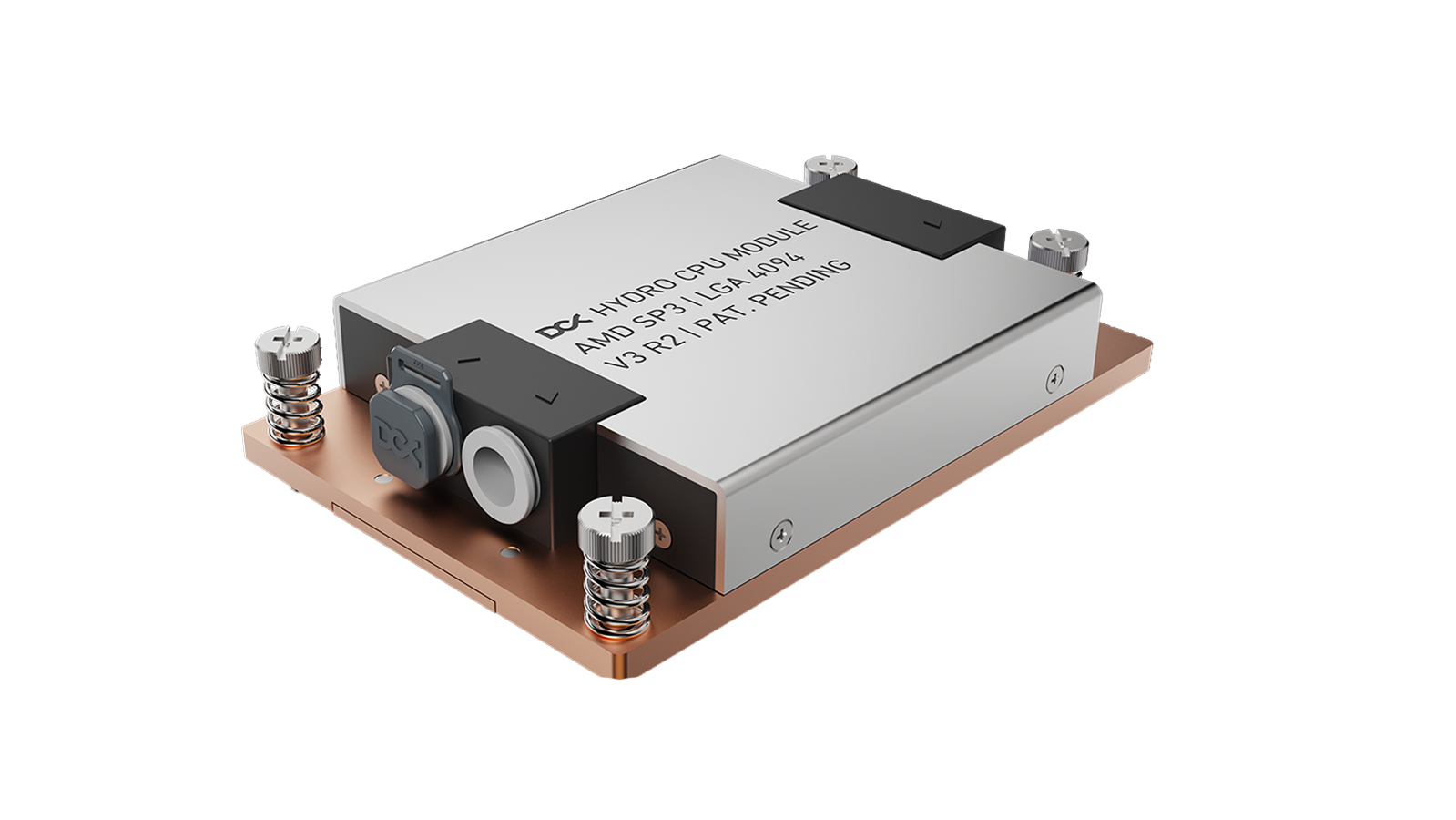

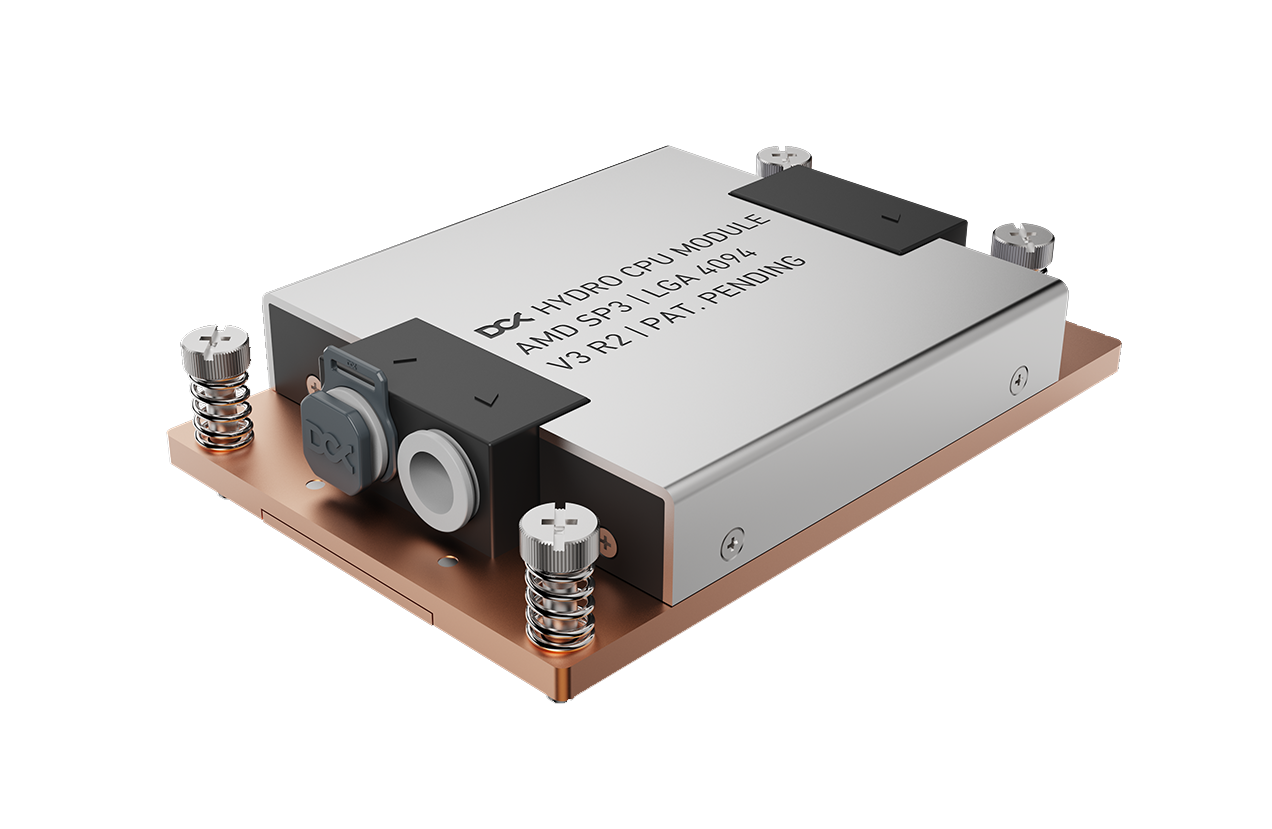

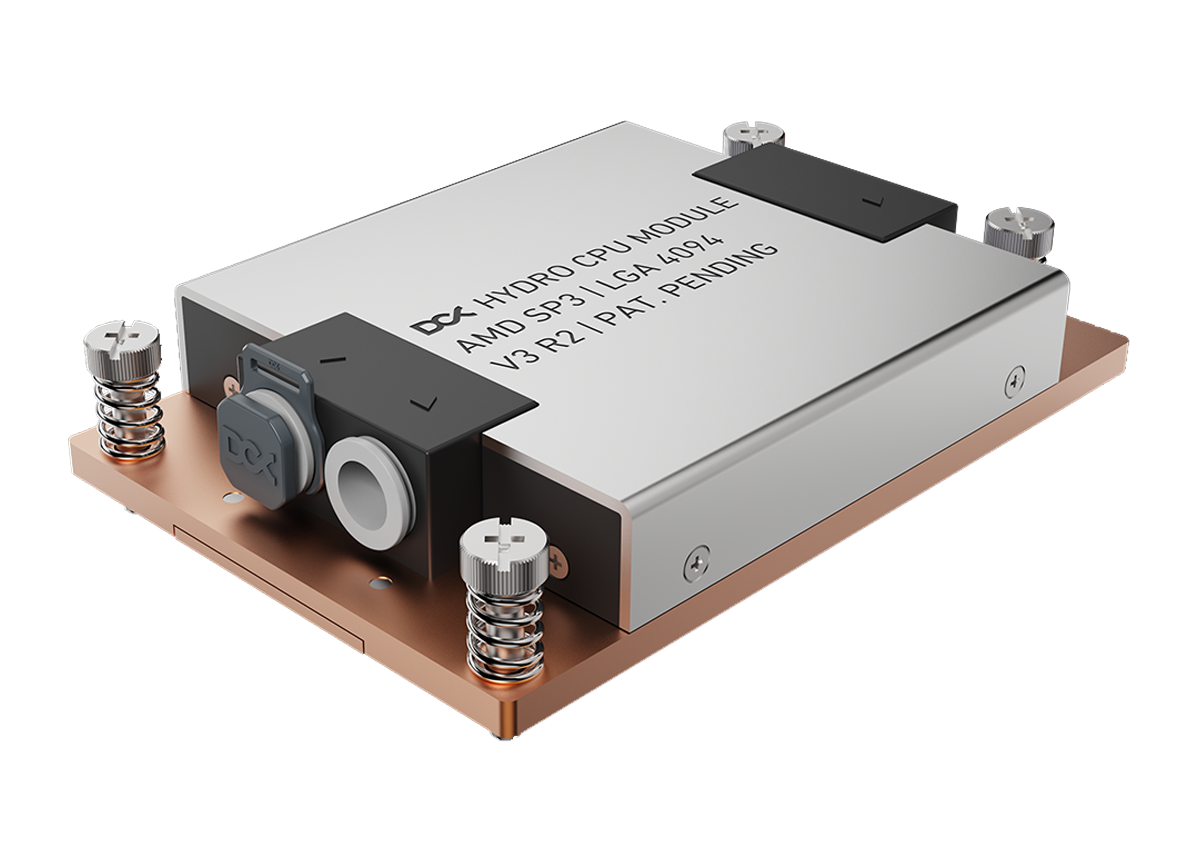

DCX HYDRO direct-contact cold plate for AMD EPYC® SP3 processors with LGA 4094 socket. A critical element of every DLC system, this unique component is the world’s first open cold plate. Open means – this module, equipped with push-to-lock couplings, is compatible with virtually every server worldwide. AMD EPYC® GENOA SP3 module features push-to-lock quick disconnect fittings, leak-proof tubing, and heat transfer bridges. That enables users to customize their cooling loop with ease, instead of being forced to buy a custom cooling loop for each server and rack. This cold plate delivers a minimum of 300W of heat transfer from the CPU at ASHRAE W3/W4 warm water inlet temperature, keeping peak, overclocked processors at the best temperature possible. DCX HYDRO coldplates cover CPUs but may be also equipped with heat transfer bridges connected on both sides which can transfer heat from VRMs, memory, and other server components. DCX HYDRO cold plate means complete safety, flexibility, long DLC system lifespan, and compatibility with any platform and design.

Capacity

Removes up to 80% of heat of the server, covering CPU and other components

Performance

From 300W to 760W of heat transfer performance using warm water

Sustainability

Requires ASHRAE W3/W4 (32-45C) water instead of power hungry chillers!

Compatibility

You can upgrade any server with AMD SP3 processors with DCX HYDRO coldplates

Overview

Introducing the DCX HYDRO direct-contact cold plate, a game-changer in data center cooling technology designed specifically for AMD EPYC® SP3 processors with LGA 4094 socket. As an integral component of any Direct Liquid Cooling (DLC) system, this revolutionary cold plate stands out as the world’s first open cold plate solution. What sets it apart is its compatibility with virtually any server worldwide, thanks to its push-to-lock couplings, offering unparalleled flexibility and ease of installation.

The DCX HYDRO cold plate boasts exceptional performance, capable of transferring a minimum of 300W of heat from the CPU even under peak loads and overclocked conditions, all while utilizing warm water at ASHRAE W3/W4 inlet temperatures. This translates to improved CPU performance and efficiency, ensuring optimal operating conditions for critical processors.

With its unique design, the DCX HYDRO cold plate not only covers the CPU but can also be equipped with heat transfer bridges to effectively dissipate heat from VRMs, memory modules, and other vital server components. This comprehensive cooling solution enhances system reliability and longevity while maintaining compatibility with any platform and design.

Key specifics highlight its impressive heat removal capabilities, removing up to 80% of the server’s heat load, thus significantly reducing the strain on HVAC systems and mechanical cooling mechanisms. Moreover, its sustainability is underscored by its reliance on warm water instead of power-hungry chillers, resulting in substantial energy savings for data center operators.

The open system architecture of the DCX HYDRO cold plate enables easy integration into existing server configurations without voiding warranties, making it an ideal choice for retrofitting and upgrading operations. Its compatibility with every server, combined with push-to-lock quick disconnect fittings, simplifies the configuration of liquid cooling loops, allowing for dense compute deployments with ease.

Furthermore, the DCX HYDRO cold plate offers a lifespan of over 10 years, ensuring long-term reliability and investment protection for data center operators. Installation is hassle-free, akin to assembling an off-the-shelf kit, with comprehensive support provided by DCX throughout the transition to liquid cooling technology.

In summary, the DCX HYDRO direct-contact cold plate redefines data center cooling, offering unparalleled performance, sustainability, and flexibility. With its innovative features and robust design, it sets a new standard for efficient and reliable CPU cooling in today’s demanding data center environments.

Features

- Open system – compatible with every server

- Improves CPU & GPU performance

- Removes >80% of heat from the servers.

- Great for retrofitting, doesn’t void warranty

- Enables dense compute with 60kW per rack or more!

- Cools the systems with hot water (W3/W4 ASHRAE)

| Ninja Column 1 | Ninja Column 2 | Ninja Column 3 | |

|---|---|---|---|

| CPU Socket | SP3 LGA 4094 | ||

| Approach temperature | W3/W4 | ||

| Heat transfer capacity | [W] | 280 | |

| Heat transfer perfomance | [W/m²K] | 469 | |

| Thermal resistance | [K/W] | 0.046 | |

| Operating pressure | [kPa] | 600 | |

| Pressure drop | [Pa] | 296 | |

| Volume flow rate | [m3/h] | 0.019 | |

| Liquid inlet temperature | [°C] | [°F] | 32 | 90 | |

| Liquid outlet temperature | [°C] | [°F] | 45 | 113 | |

| Height | [mm] | 30 | |

| Active surface area | [m²] | 0.046 | |

| Filtering requirement | [μm] | 50 | |

| Ninja Column 1 | Ninja Column 2 | Ninja Column 3 | |

|---|---|---|---|

| Approach temperature | W3/W4 | ||

| Maximum heat transfer capacity | [W] | 2381 | |

| Heat transfer perfomance | [W/m²K] | 5176 | |

| Thermal resistance | [K/W] | 0.0042 | |

| Operating pressure | [kPa] | 600 | |

| Pressure drop | [Pa] | 7227 | |

| Volume flow rate | [m3/h] | 0.207 | |

| Liquid inlet temperature | [°C] | [°F] | 32 | 92 | |

| Liquid outlet temperature | [°C] | [°F] | 42 | 108 | |

Features

- Open system – compatible with every server

- Improves CPU & GPU performance

- Removes >80% of heat from the servers.

- Great for retrofitting, doesn’t void warranty

- Enables dense compute with 60kW per rack or more!

- Cools the systems with hot water (W3/W4 ASHRAE)

System Build

AMD EPYC® SP3 LGA 4094 Coldplate

DCX HYDRO coldplates are OPEN, which means you can order direct chip cooling components in the same way as server hard drives or expansion cards, and configure your own DLC loop. DCX provides CPU & GPU coldplates equipped with quick disconnect fittings, special tubing, manifolds, and CDUs. This way datacenter operators are not forced to order custom proprietary loops and can reuse DCX Coldplates in different servers having the same CPU socket. DCX HYDRO system means flexibility, long lifetime, better efficiency of your server, and total compatibility with any platform and design.

Get in Touch

We will advise, guide and support – the ideas are always free of charge!

Get your custom solution:

We need basic information to design custom liquid cooling system:

- Quantity and general specification and dimensions of servers, ICT systems or other to be cooled components, along with power allocation per device or rack.

- Brief overview of your project along with your main objective: better performance, water savings, energy efficiency, heat reuse, higher density?

- Preferred liquid cooling technology: direct chip – coldplate system or immersion solution? Planned heat rejection or heat recovery strategy.

- Country & city nearby planed location for climate data, heat transfer performance & shipping cost estimate.