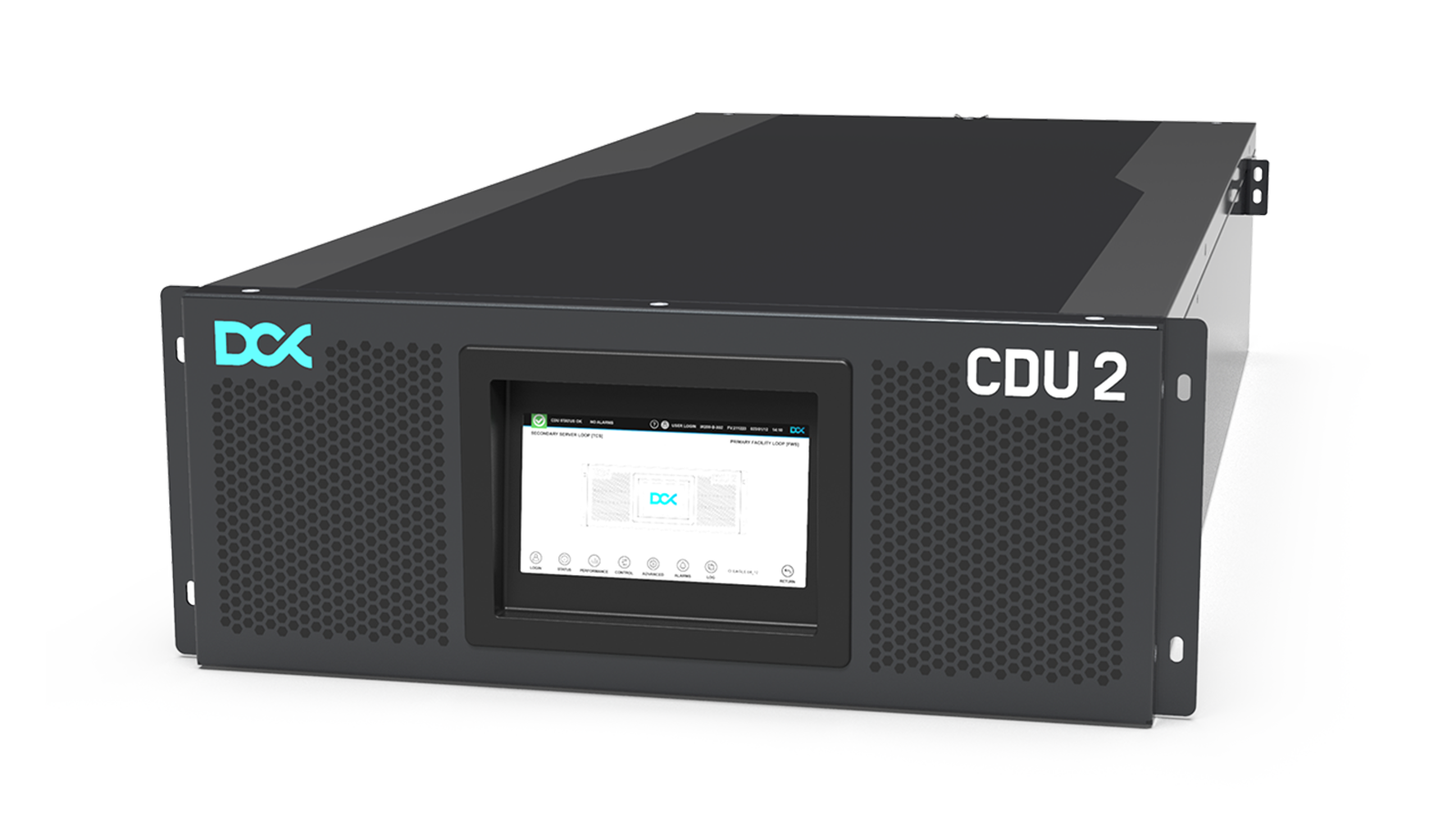

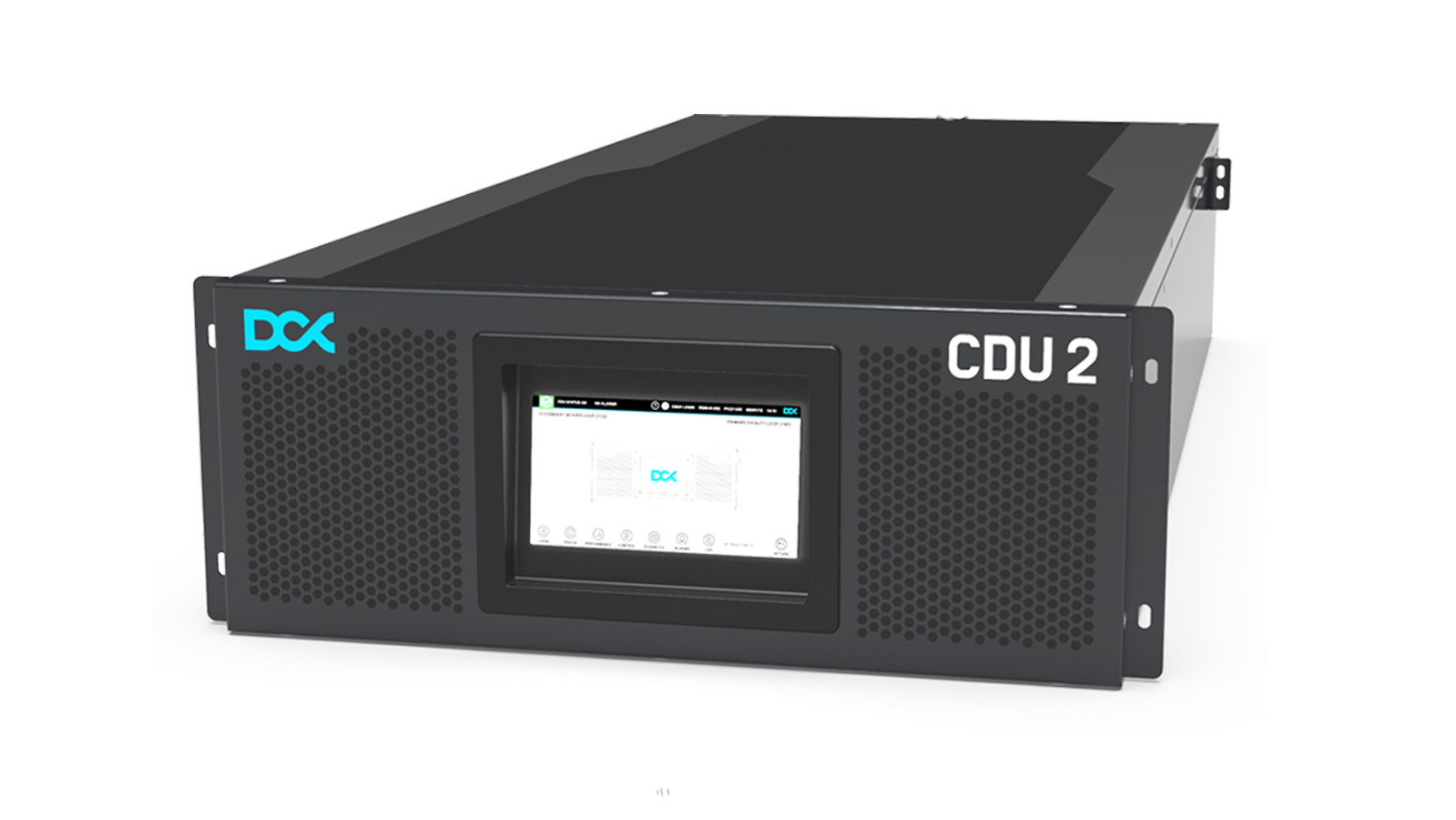

An excellent all-rounder for rack level cooling

DCX HYDRO CDU 2 is a rack-based Coolant Distribution Unit designed to cool individual high-density server racks. This compact 4U CDU is equipped with unique immersion pumps and delivers over 170-200kW heat transfer capacity. It is a perfect solution to provide responsive, high-capacity cooling for high-performance servers, and it only requires ASHRAE W3/W4 warm water to solve cooling challenges. CDU features a redundant pump design, dynamic condensation-free control, automatic coolant leveling, automatic leak detection, and complete remote control of all important parameters. This CDU combined with DCX Liquid Distribution Manifolds can be integrated into all standard server racks providing the exact, optimal cooling performance that your servers need, keeping your operation environmentally sustainable.

Capacity

Up to 150 servers or 2 server racks per one CDU!

Performance

From 170 to over 200kW of heat transfer capacity!

Sustainability

Enables heat reuse with up to 60°C return temperature!

Energy Efficiency

Adaptive energy consumption up to 3kW per 2 server racks

Overview

The DCX HYDRO CDU 2 is a rack-based Coolant Distribution Unit (CDU) designed to cool high-density server racks with unparalleled efficiency. This compact 4U CDU features advanced immersion pumps, delivering an impressive 170-200kW of heat transfer capacity, making it the highest-performing 4U CDU in the industry. Capable of supporting over 150 servers across two racks, it is the ideal solution for high-performance servers requiring responsive, high-capacity cooling.

Requiring only ASHRAE W3/W4 warm water, the DCX HYDRO CDU 2 effectively addresses cooling challenges in power-dense environments. It comes equipped with a redundant pump design for reliability, dynamic condensation-free control, automatic coolant leveling, leak detection, and full remote management of all critical parameters. When paired with DCX Liquid Distribution Manifolds, this CDU can be seamlessly integrated into standard server racks, ensuring precise, optimal cooling performance while promoting environmental sustainability.

Features

- Supports twice as many servers, CPU’s and GPU’s than other CDU’s

- Multi-stage immersion pumps deliver twice the pressure and flow rate of standard pumps.

- Enterprise-class system high availability & redundancy

- Adaptive efficiency, loop separation and condensation control.

- Complete portfolio of 7 CDUs tailored to meet diverse cooling requirements

- Wide range of systems, ranging from 100kW per 1 rack to 5MW and 100 server racks per single CDU.

| Ninja Column 1 | Ninja Column 2 | Ninja Column 3 | Ninja Column 4 | Ninja Column 5 | |||

|---|---|---|---|---|---|---|---|

| Transport weight [kg / lbs] | 95 / 209.4 | ||||||

| Noise Level [dB] | 65 | ||||||

| Working environment T&H | 0~50C°/ RH5~85% | ||||||

| Power specifications | 2×1P AC220V 50/60Hz | ||||||

| T-V coefficient [C*L] | 3.8×10⁴ | ||||||

| Max. Power consumption [kW] | 3 | ||||||

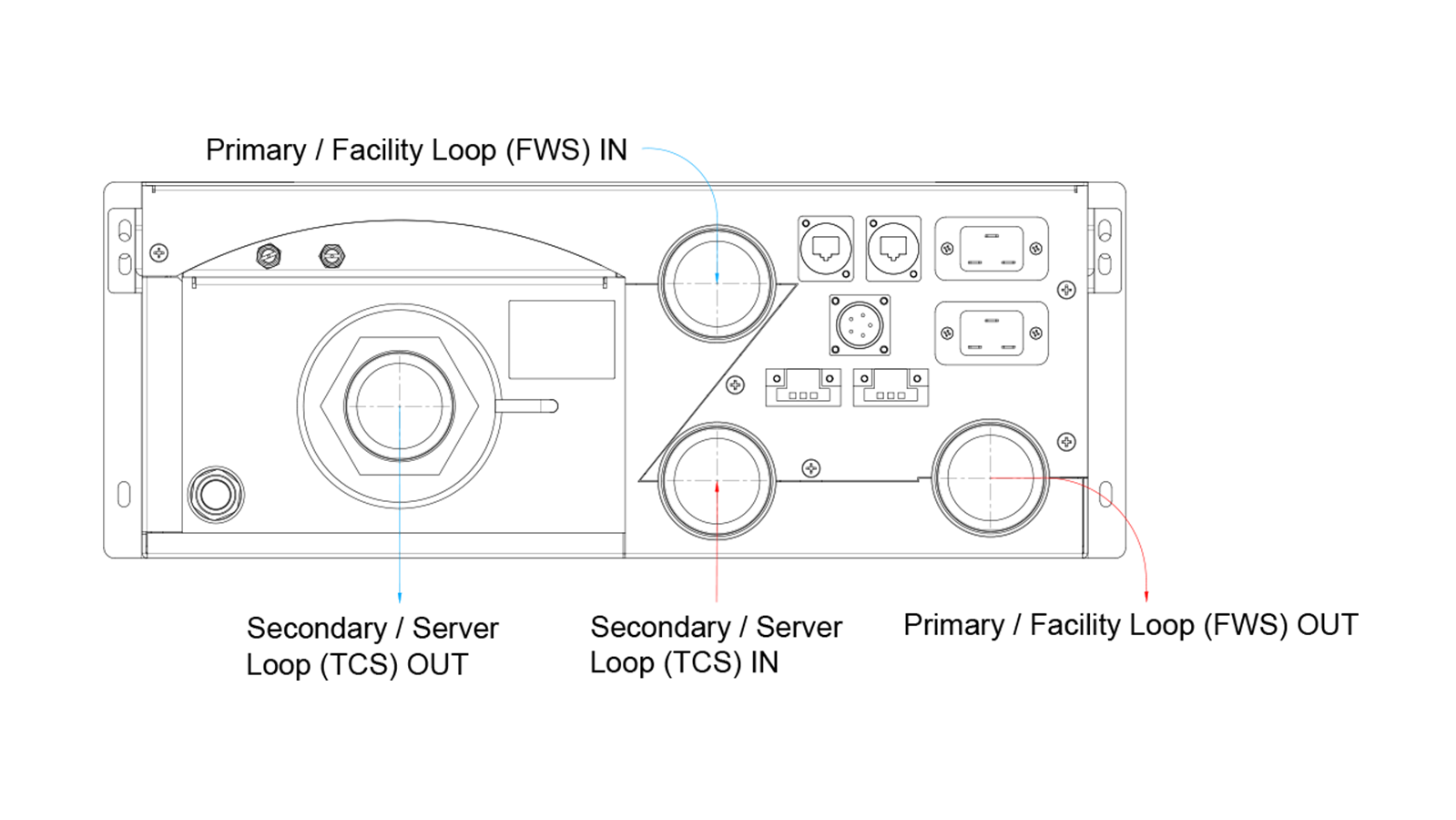

| TCS liquid connector style and dimension | Tri-Clamp 1.5" | ||||||

| FWS liquid connector style and dimension | Tri-Clamp 1.5" | ||||||

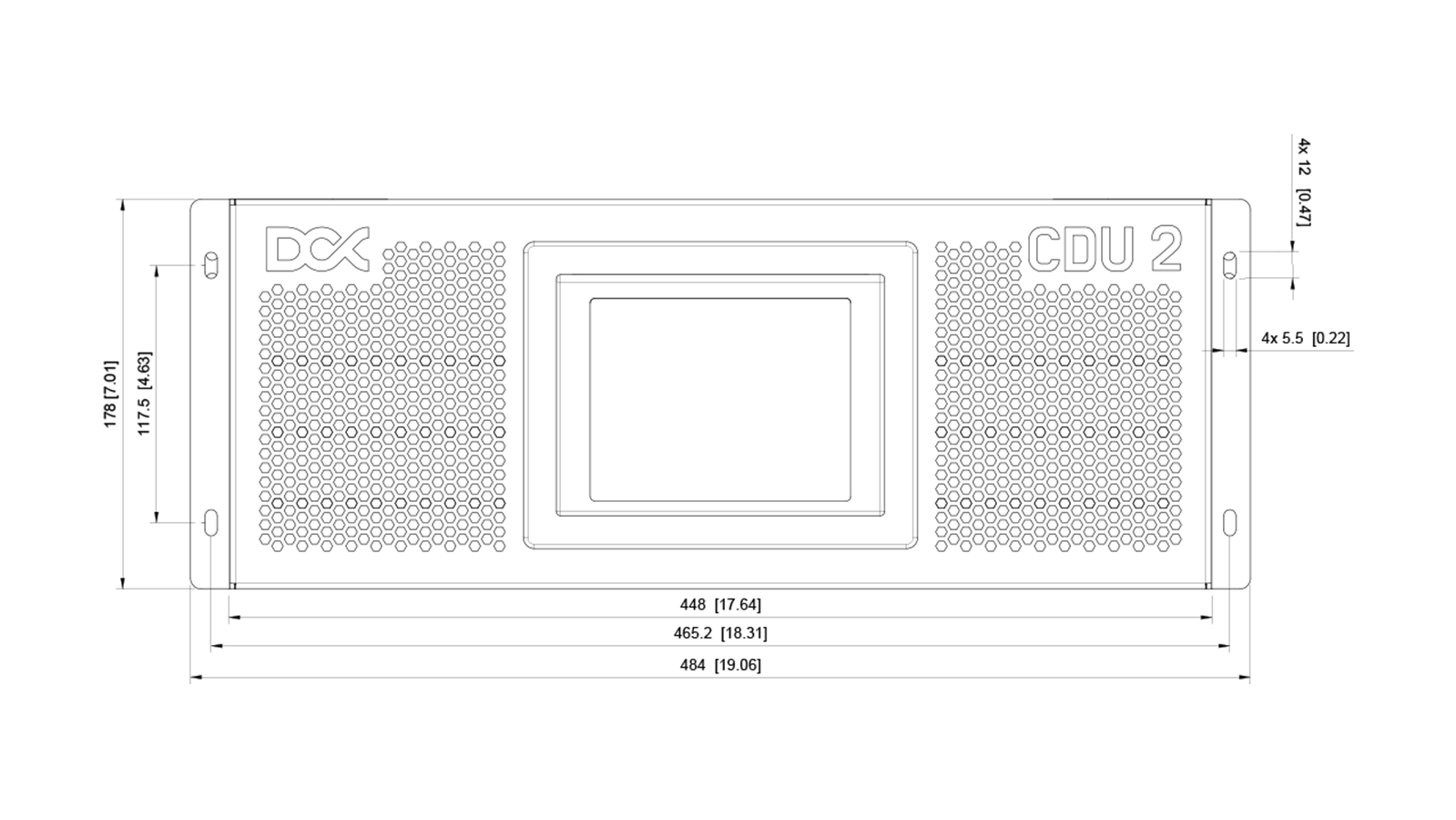

| Height [mm] | Width [mm] | Depth [mm] | 178 | 484 | 1052 | ||||||

| Operation weight [kg / lbs] | 118 /260.1 | ||||||

| Product model | CDU 2 | ||||||

| Cooling capacity margin | -6% | 14% | |||||

| Rated outlet temperature [°C ] | 48.6 | 40 | 46.8 | 40 | |||

| Rated inlet temperature [°C] | 35 | 53.6 | 35 | 51.8 | |||

| Output rated dP (bar) | / | ≥2.3 | / | ≥1.4 | |||

| Flow [m3/h] | 6 | 6 | 8.4 | 8.4 | |||

| Coolant | Facility water | DI-water | Facility water | DI-water | |||

| Operation condition | Primary side | Secondary side | Primary side | Secondary side | |||

| Approach temperature [°C] | 5 | 5 | |||||

| Cooling capacity [kW] | 200 | ||||||

Features

- Supports twice as many servers, CPU’s and GPU’s than other CDU’s

- Multi-stage immersion pumps deliver twice the pressure and flow rate of standard pumps.

- Enterprise-class system high availability & redundancy

- Adaptive efficiency, loop separation and condensation control.

- Complete portfolio of 7 CDUs tailored to meet diverse cooling requirements

- Wide range of systems, ranging from 100kW per 1 rack to 5MW and 100 server racks per single CDU.

System Build

CDU 2 InRack Cooling Distribution Unit

InRack 4U CDU, with 200 kW heat transfer capacity at average 10°C – 15°C approach temperature and 300kW at approach temp claimed by competitive systems. Over 2 x more efficient than comparable in rack 4U CDU’s, will effectively cool more racks than any other 4U CDU. This rack based unit is equipped with 2 redundant multistage immersion pumps and can effectively cool 2 racks of AI workloads or high-powered HPC systems with 2 x higher pressure and flow rate than any other solution.

The system has a clamp connection for easy and quick installation. With the double pump redundancy design, replacement and maintenance are simple, ensuring great dependability. Maintenance can be performed without a shutdown in the case of a pump or power outage, or if the filter gets clogged. Furthermore, the system has a complete real-time monitoring feature for operating parameters. Its top computer connection interface includes two redundant RS485 ports and two redundant RJ45 ports, which use the default communication protocols Modbus RTU and Modbus TCP/IP.

Get in Touch

We will advise, guide and support – the ideas are always free of charge!

Get your custom solution:

We need basic information to design custom liquid cooling system:

- Quantity and general specification and dimensions of servers, ICT systems or other to-be-cooled components, along with power allocation per device or rack.

- A brief overview of your project along with your main objective: better performance, water savings, energy efficiency, heat reuse, higher density?

- Preferred liquid cooling technology: direct chip – coldplate system or immersion solution? Planned heat rejection or heat recovery strategy.

- Country & city nearby planed location for climate data, heat transfer performance & shipping cost estimate.