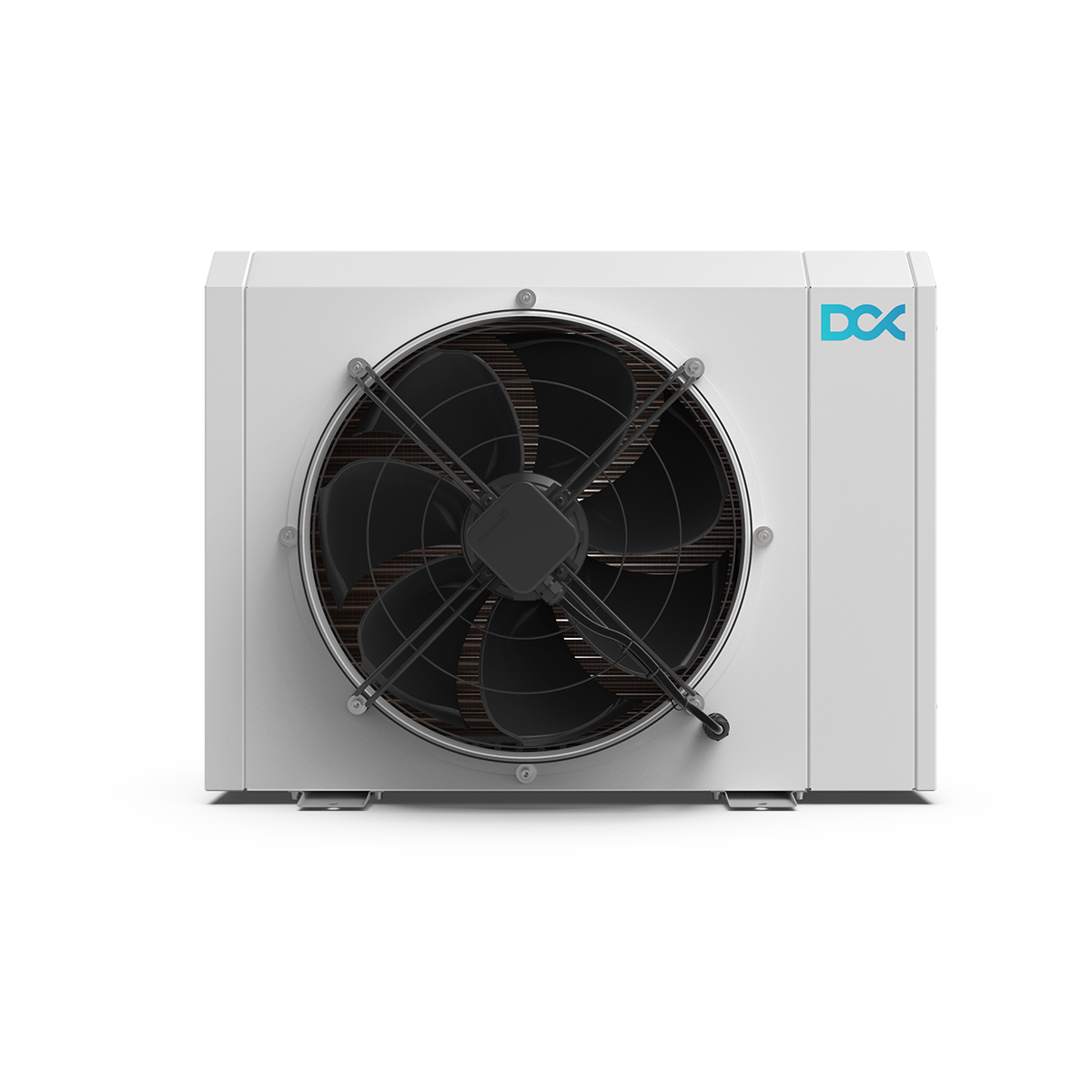

The DCX ICP15 is a game-changer for industrial cooling. This compact and powerful dry cooler is integrated with a pump and adaptive fan control, making it the most efficient and reliable solution on the market. Delivers 15.87 kW of cooling capacity at 35°C and 21 kW at 25°C, ensuring optimal operating conditions for your equipment. Over 2 times more effective than traditional oil coolers, ideal for even the most demanding thermal loads. Integrated pump and compact design eliminate the need for additional devices, saving you time and money. Utilizes ambient air for cooling, requiring no water and reducing your environmental footprint. Adaptive fan control automatically adjusts fan speed based on cooling demands, ensuring optimal performance while minimizing noise levels. Remote monitoring and control of operating parameters provide complete control and peace of mind.

The ICP15 is the perfect choice for cooling industrial machinery and equipment, IT and telecommunications systems and cryptocurrency mining equipment.

Capacity

The ICP 15 delivers 15.87 kW of cooling capacity at 35°C, ideal for demanding applications.

Performance

Over 3 times more effective than traditional oil coolers, ensures optimal operating conditions.

Sustainability

Utilizing ambient air for cooling, requires no water and reduces your environmental footprint.

Energy Efficiency

Adaptive energy consumption up to 1.1 kW, adaptive fan control automatically adjusts speed.

Overview

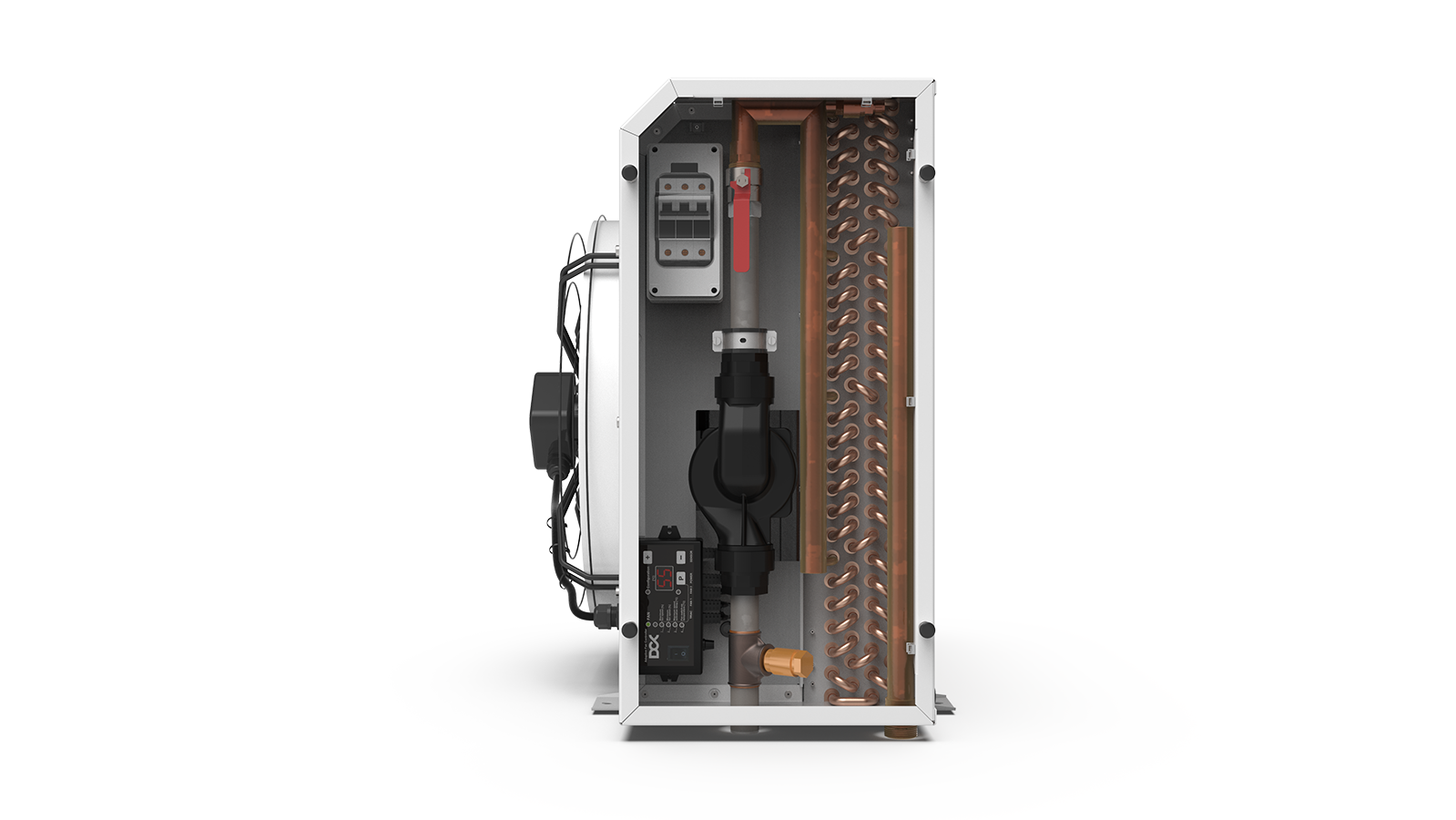

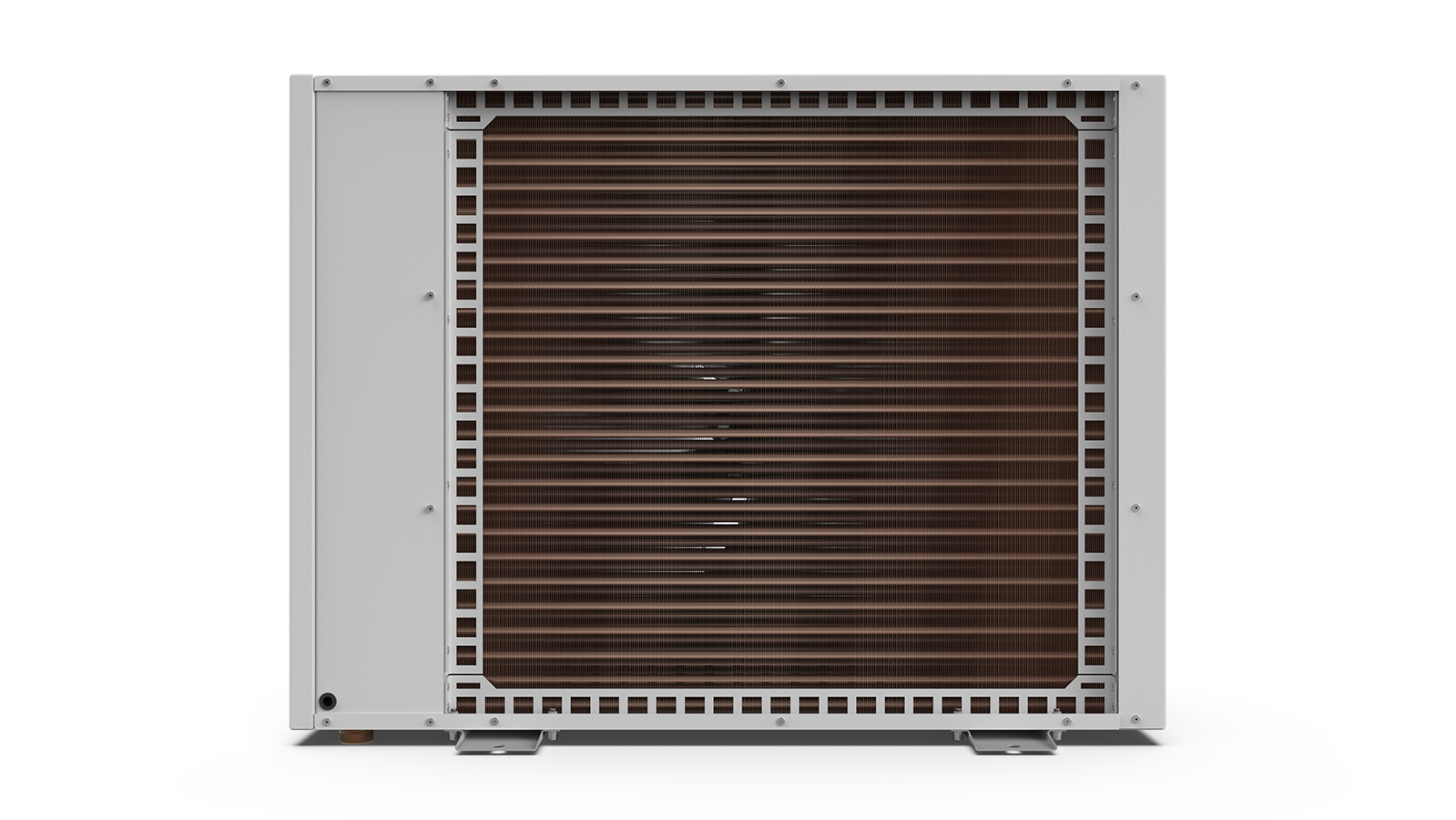

ICP15 is an Industrial dry cooler combined with integrated pump and adaptive fan control. Equipped with adaptive fan controller which controls the speed of the fans, so they operate as silent as possible. ICP15 may be combined with heat reuse loop and is ideally sized for home mining operations. Embrace a revolution in industrial cooling with the DCX ICP15, a compact yet powerful dry cooler designed to deliver exceptional efficiency, reliability, and environmental consciousness. This innovative solution seamlessly integrates a built-in pump and intelligent fan control system, surpassing the competition as the ideal choice for your cooling needs.

Experience unparalleled cooling performance, with over 15.87 kW of heat transfer capacity at 35°C and an impressive 21 kW at 25°C. The ICP 15 effortlessly maintains optimal operating conditions for your equipment, even in demanding environments. Three times more effective than conventional oil coolers, the ICP15 delivers superior thermal management, ensuring your equipment operates at peak performance for extended periods. Eliminate the need for additional equipment and streamline your setup process.

The integrated pump and compact design of the ICP15 minimize space requirements and simplify installation, saving you valuable time and resources. Enjoy remote monitoring and control capabilities for all operating parameters of the ICP15. This allows you to maintain complete system control and gain real-time insights into your cooling process, ensuring peace of mind and the ability to adjust settings as needed.

Features

- Broad Range of cooling systems – from integrated 15-40kW cooling & pumping systems, to industrial dry coolers in the range 120-240kW up to rugged 1-2MW platforms

- Electronically controlled with automatic fan programming results with low noise levels

- Optimized for liquid cooling temperatures threshold

- Optional Adiabatic Spray / Panel System

- Compact systems with highly efficient geometry result with maximum performance & minimum footprint

- Build with rigid frames and sized to standard dimensions which enables mobility and easy relocation if needed

- CE Marked, PED EN(2014/68/EU) compliant, UL / ETL compliant

| Ninja Column 1 | Ninja Column 2 |

|---|---|

| Application | Small scale proof of concept systems or edge applications |

| Cooling capacity (Ambient temp=35°C) [kW] | 15 kW |

| Cooling capacity (Ambient temp=25°C) [kW] | 21 kW |

| Dimensions [mm] | 875 x 460 x 665 |

| Fans | 1 x 500 mm |

| Noise level [dB(A)] | 58-62 |

| Maximum power consumption [kW] | 1.1 |

| Power Standard | 230-240V/1Ph/50/60 Hz |

| Fittings | 1" / DN25 |

| Control System | Adaptive Fan Controller with temperature sensor |

| Fluid temperature In / Out [°C] | 60 / 40 |

| Transport weight [kg]|[lb] | 40 | 88 |

| Nominal volume flow [mᶾ/h] | 0.65 |

| Pressure drop (bar) | 0.34 |

Features

- Broad Range of cooling systems – from integrated 15-40kW cooling & pumping systems, to industrial dry coolers in the range 120-240kW up to rugged 1-2MW platforms

- Electronically controlled with automatic fan programming results with low noise levels

- Optimized for liquid cooling temperature threshold

- Optional Adiabatic Spray / Panel System

- Compact systems with highly efficient geometry result with maximum performance & minimum footprint

- Build with rigid frames and sized to standard dimensions which enables mobility and easy relocation if needed

- CE Marked, PED EN(2014/68/EU) compliant, UL / ETL compliant

System Build

ICP 15 Adaptive Cooling / Pumping System

The ICP 15 Adaptive Cooling is a next-generation dry cooler designed to deliver unmatched flexibility and efficiency in various cooling applications. Unlike traditional dry coolers, the ICP 15 utilizes intelligent technology and innovative features to optimize performance and adapt to changing conditions. Here’s a closer look at its key components: Copper construction offers excellent durability and resistance to corrosion, ensuring long-lasting performance. These fans are specifically chosen for their efficiency in moving large volumes of air with low noise levels. Equipped with integrated variable frequency controller that adjust fan speed based on real-time cooling demand. This optimizes energy consumption and minimizes noise generation. The VFDs work in conjunction with the control system for predictive and adaptive operation. Offers various operating modes, such as free cooling, partial load, and full load, allowing for flexible adaptation to changing cooling needs. Constructed from galvanized steel with a special weatherproof coating for exceptional durability and corrosion resistance. Withstands harsh outdoor environments, including extreme temperatures, heavy snowfall, strong winds, and high humidity. Integrated connections for the process fluid ensure seamless integration into your system.

Sustainable high performance computing

As computing power constantly increases, liquid cooling becomes a necessary solution to replace conventional air cooling. DCX HYDRO SYSTEM stands out as the most powerful, compact, sustainable, and energy-efficient data center cooling technology available today.

Get in Touch

We will advise, guide and support – the ideas are always free of charge!

Get your custom solution:

We need basic information to design custom liquid cooling system:

-

Quantity and general specification and dimensions of servers, ICT systems or other to be cooled components, along with power allocation per device or rack.

-

Brief overview of your project along with your main objective: better performance, water savings, energy efficiency, heat reuse, higher density?

-

Preferred liquid cooling technology: direct chip – coldplate system or immersion solution? Planned heat rejection or heat recovery strategy.

-

Country & city nearby planed location for climate data, heat transfer performance & shipping cost estimate.

Explore DCX HYDRO Components

More performance, better reliability, and more comfort. Nothing is better.

DCX HYDRO Universal Coldplates Portfolio

Instead of proprietary custom loops for one server only - a complete portfolio of open direct chip cooling cold-plates that enable you to retrofit any server!

DCX Server Immersion

Cooling Portfolio

Immersion delivers 100% of heat rejection but comes with steep price. DCX disrupts the market introducing standard sized, affordable, high capacity immersion systems