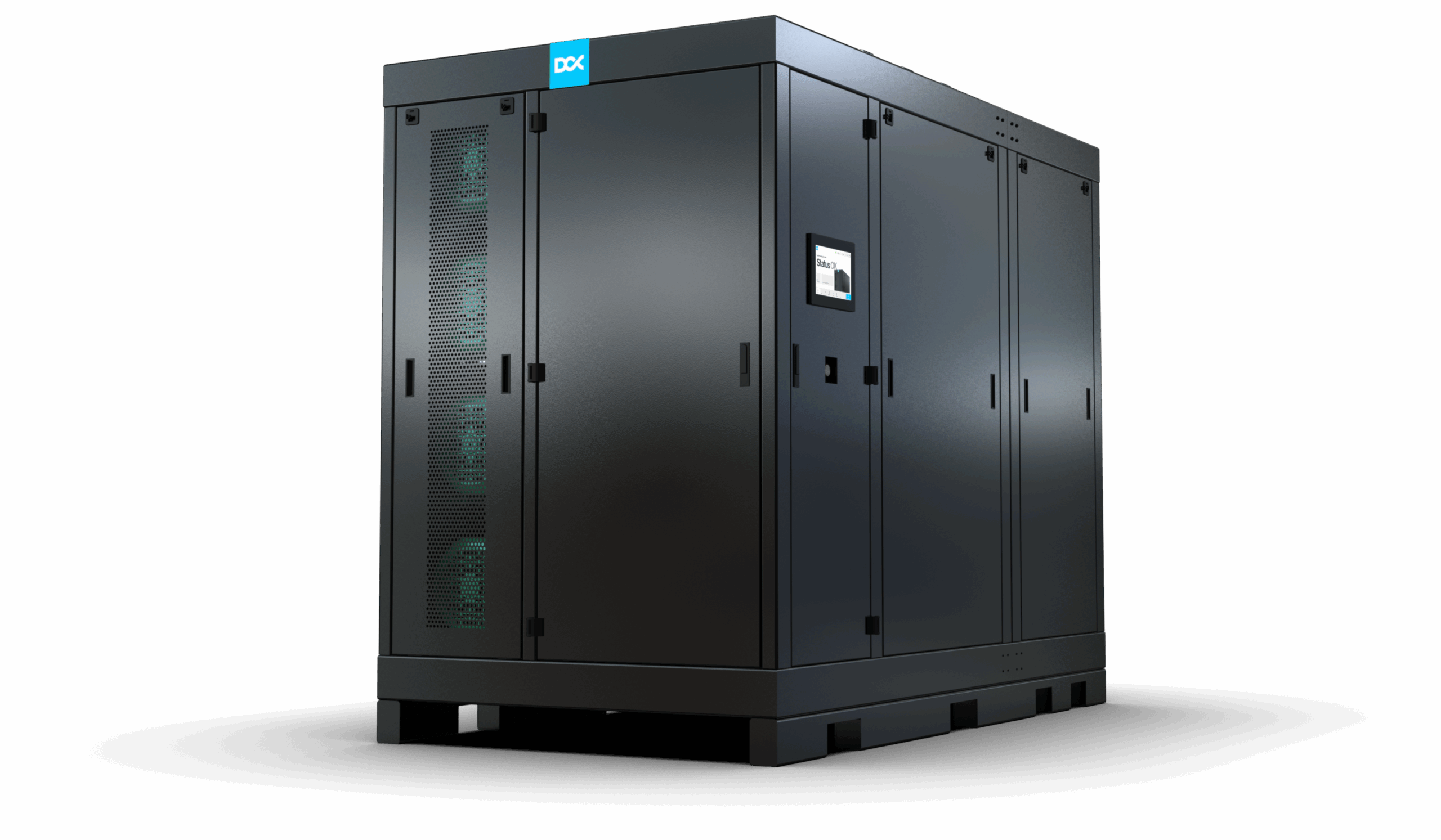

DCX FDU V2 ΔT2 8 MW

Facility Coolant Distribution Unit

Capacity

Up to 80 AI racks (42U config) per one FDU!

Performance

An elite performance of 8MW heat transfer capacity.

Sustainability

Enables heat reuse with up to 60°C return temperature!

Power density

8MW of heat transfer in just 4.5 m² (48 sq. ft.) form factor.

Overview

DCX HYDRO FDU – FACILITY DISTRIBUTION UNIT 8MW CDU for hyperscale class deployments. New unique facillity sized CDU designed to cool a group of high-density server racks. Cost-effective but enterprise-class CDU, delivers over 5MW heat transfer capacity at 2°C approach temperature. FDU features all advanced capabilities: N+1 redundant pump design, dynamic condensation-free control, automatic coolant leveling, automatic leak detection and complete remote control of all important parameters. A perfect solution that provides responsive, high-capacity cooling for HPC or GPU server nodes, and it only requires ASHRAE W3/W4 warm water to solve all cooling challenges of power–dense racks. The compact dimensions of FDU (L 4.8m/15.8ft | W 1.8m/5.9ft | H 2.4m/7.9ft) allow for quick retrofitting of existing data halls. FDU will fit any environment withoverhead or technical floor pipe routing. The system can be integrated with all standard server racks providing energy-efficient cooling & intelligent controls.

Features

- From 2 to 8 MW per single unit all the way to up to 10MW in a dual stack configuration.

- Enterprise-class system of high availability & redundancy

- Adaptive efficiency, loop separation and condensation control.

- Redundant pump system: Wilo Industrial Centrifugal Pumps with automatic failover and built-in resiliency

- Fully remote temperature monitoring & reporting.

Features

- Supports twice as many servers, CPU’s and GPU’s than other CDU’s

- Multi-stage immersion pumps deliver twice the pressure and flow rate of standard pumps.

- Enterprise-class system high availability & redundancy

- Adaptive efficiency, loop separation and condensation control.

- Complete portfolio of 7 CDUs tailored to meet diverse cooling requirements

- Wide range of systems, ranging from 100kW per 1 rack to 8MW and 100 server racks per single CDU

System Build

Facility Distribution Unit

This large scale, facility sized Coolant Distribution unit is 4,8 meters long, 1,8 meters wide and 2,4 meters tall. The compact dimensions of FDU (LWH 4.8×1.8×2.4 m) allow for quick retrofitting of existing data halls. This CDU will fit any environment withoverhead or technical floor pipe routing. The system can be integrated with all standard server racks providing energy-efficient cooling & intelligent controls. FDU has a built-in water treatment station to keep high purity and quality of cooling medium without PG25 performance drop.

Get in Touch

We will advise, guide and support – the ideas are always free of charge!

Get your custom solution:

We need basic information to design custom liquid cooling system:

-

Quantity and general specification and dimensions of servers, ICT systems or other to be cooled components, along with power allocation per device or rack.

-

Brief overview of your project along with your main objective: better performance, water savings, energy efficiency, heat reuse, higher density?

-

Preferred liquid cooling technology: direct chip – coldplate system or immersion solution? Planned heat rejection or heat recovery strategy.

-

Country & city nearby planed location for climate data, heat transfer performance & shipping cost estimate.